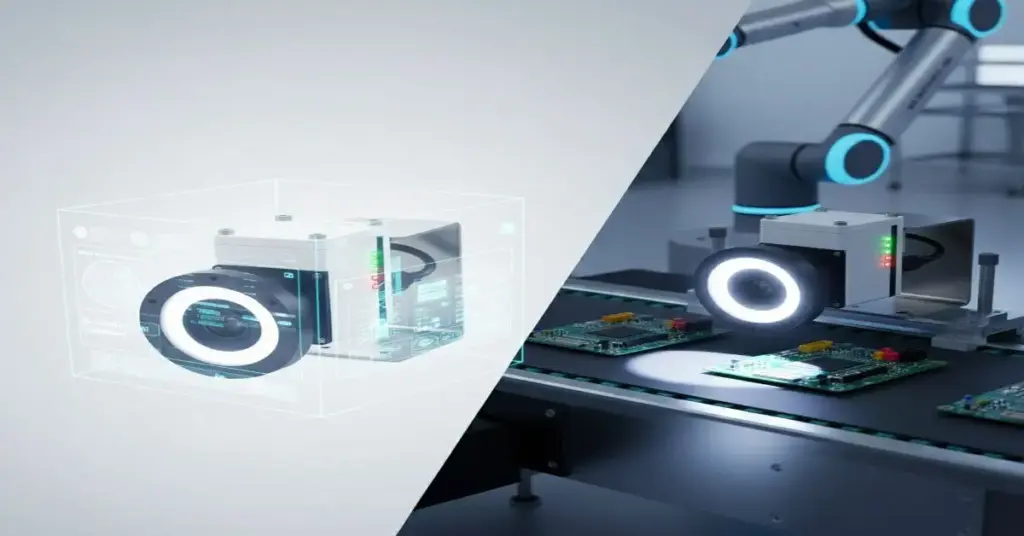

How Vision & Imaging Sensors Transform Automated Inspection Systems

How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial. Vision and imaging sensors are now key components of automated inspection systems, providing fast, reliable, and precise visual analysis that replaces slower, error-prone manual checks. ADYAA, offers advanced vision and imaging sensors that help manufacturers enhance quality, reduce defects, and increase overall production efficiency. What Are Vision & Imaging Sensors? Vision and imaging sensors are compact devices that integrate a camera, illumination, optics, and embedded image-processing software into a single industrial-grade unit. These sensors capture images of products or processes and analyze visual features such as shape, size, color, and defects in real time. Key capabilities include: Multiple Feature Checks: Inspect many characteristics from a single image, including presence, orientation, and print quality. Contour & Color Processing: Detect edges, shapes, and subtle color differences for accurate inspection. Part Localization: Identify and align objects precisely, even if they are not perfectly positioned. Integrated Illumination and Processing: Operate independently without needing an external computer. Vision sensors at ADYAA are designed for industrial environments and can handle high-speed production and complex inspection tasks across multiple industries. How Vision & Imaging Sensors Improve Automated Inspection Vision sensors enhance automated inspection by making processes faster, more accurate, and consistent: High-Speed Evaluation: Inspect thousands of products per minute to keep production lines moving efficiently. Consistent Quality Control: Provide objective and repeatable inspection results, reducing human errors. Early Defect Detection: Identify defects before products leave the line, reducing waste and rework. Data for Process Improvement: Collect visual data for traceability, trend analysis, and process optimization. Seamless Integration: Work with PLCs and robotics for coordinated automation and inspection tasks. Applications of Vision & Imaging Sensors Vision and imaging sensors are widely used to ensure quality and efficiency in multiple industries: Presence & Completeness Checks: Confirm that all components are assembled correctly. Dimensional Measurement: Verify that parts meet required specifications. Reading Codes & Text: Perform barcode scanning and OCR for traceability. Surface Defect Detection: Detects scratches, dents, or surface flaws. These applications demonstrate the importance of vision sensors in automotive, electronics, packaging, food processing, and pharmaceutical manufacturing. Conclusion Vision and imaging sensors are transforming automated inspection systems by delivering fast, accurate, and consistent quality checks. Integrating vision sensors from ADYAA Made by Baumer allows manufacturers to reduce waste, improve product quality, and collect valuable data for continuous process improvement. Investing in advanced vision and imaging technology is key to creating smarter, more efficient, and reliable manufacturing operations. Take the Next Step Explore ADYAA’s Vision & Imaging Sensors Collection Contact ADYAA’s technical team for expert advice How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →

IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability

IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve efficiency, enhance safety, and prevent downtime with predictive maintenance, remote monitoring, and smart automation solutions. Why IoT and Automation Matter Industrial operations are rarely simple. A missed maintenance alert, delayed data, or human error can cost thousands—or even millions. IoT and automation are no longer optional—they are critical for: Operational efficiency Safety and compliance Minimizing downtime Callout Box:ADYAA, Tip for Plant Managers: Digital systems act as invisible sentinels, monitoring operations 24/7 and reducing risks before they become costly problems. The Cost of Inefficiency Without IoT Inefficiency shows up in several ways: Unplanned Downtime: Machines fail unexpectedly. Safety Hazards: Human monitoring errors in hazardous environments. Energy and Material Waste: Manual processes consume more resources. Insight: Adopting ADYAA IoT and automation allows plant managers to proactively reduce risks and improve performance. Suggested Image: Industrial plant with IoT sensors – Alt: “Industrial IoT sensors monitoring machinery” How IoT and Automation Transform Industrial Operations Modern industrial operations demand precision, insight, and control. Here’s how smart technologies make a difference: Predictive Maintenance – Stop Downtime Before It Happens Manual maintenance schedules are reactive and costly. Solution: IoT sensors + AI analytics How it Works: Sensors track temperature, vibration, and performance in real-time. AI predicts failures before they occur. Benefit: Continuous production with minimal unplanned downtime. Suggested Icon/Image: Gear with sensor – Alt: “Predictive maintenance using IoT sensors” Process Automation – Consistency & Efficiency Manual operations introduce variability and errors. Solution: PLCs and automation software How it Works: Automated systems control machine sequences, fluid levels, and assembly lines with precision. Benefit: High-quality output and efficient resource use. Suggested Icon/Image: Robotic arm on production line – Alt: “Industrial automation controlling production line” Remote Monitoring – Control Operations Anywhere Many plants operate in hazardous or remote areas. Solution: IoT gateways + cloud dashboards How it Works: Real-time data is sent to dashboards, allowing engineers to monitor and adjust operations remotely. Benefit: Continuous operational control and safety, even off-site. Suggested Icon/Image: Cloud dashboard – Alt: “IoT remote monitoring dashboard” Data-Driven Decision Making – Insights That Drive Action Data is valuable only if it informs action. Solution: Industrial AI + analytics platforms How it Works: Aggregated sensor data identifies trends and anomalies, allowing managers to optimize production schedules and improve safety protocols. Benefit: Smarter decisions, less waste, safer operations. Suggested Icon/Image: Analytics graph – Alt: “Data-driven decision making in industrial operations” Why IoT and Automation Projects Fail (And How to Avoid It) Even advanced systems fail without proper management: Poor Integration: Disconnected devices lead to fragmented insights. Insufficient Training: Operators misinterpret dashboards. Neglecting Maintenance: Sensors and PLCs need periodic checks. Callout Box: Partner with experienced vendors who understand industrial processes and system integration. Secure Your Industrial Future Efficiency and safety cannot rely on human vigilance alone. IoT and automation provide: Predictive intelligence Precise control Actionable insights Investing in smart industrial systems ensures your plant stays future-ready, efficient, and risk-free. Explore ADYAA’s Industrial Sensors Collection Contact ADYAA’s technical team for expert advice How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →

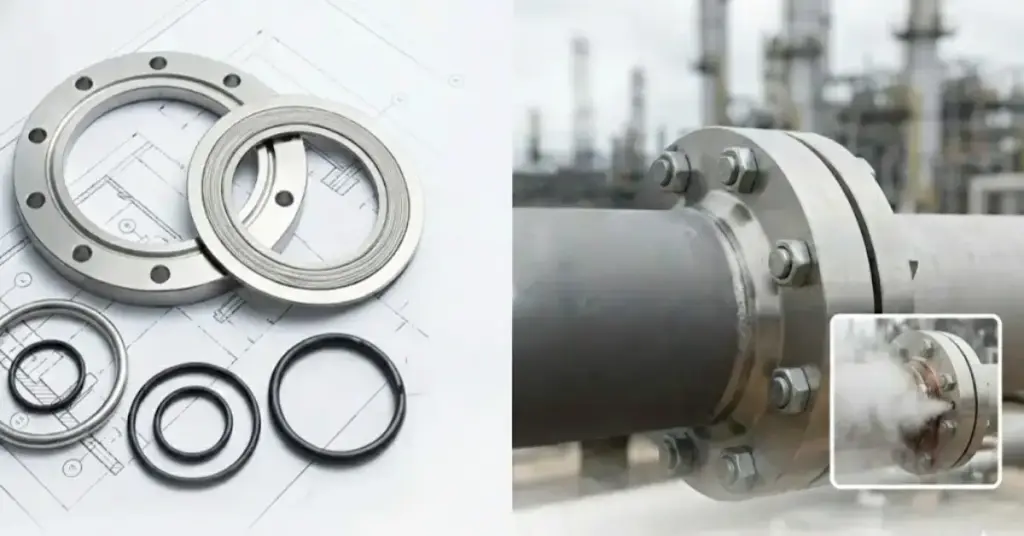

Gaskets vs O-Rings: Which Sealing Solution Is Right for You?

Gaskets vs O-Rings: Which Sealing Solution Is Right for You? In any fluid handling system, the weakest point is always the connection. Whether you are bolting two pipe flanges together or sealing a moving piston, you need a barrier that prevents leaks. This brings us to the most common question in industrial sealing: what is the difference between Gaskets vs O-Rings? While both devices serve the same ultimate purpose—keeping fluids in and contaminants out they function differently and are designed for distinct environments. ADYAA, supply both high-performance gaskets and precision O-rings. In this guide, we break down the battle of Gaskets vs O-Rings to help you select the right solution for your application. Gaskets vs O-Rings for: Mechanical Engineers, Maintenance Technicians, Procurement Officers. 1. What Is a Gasket? (The Static Specialist) A gasket is a flat seal designed to fill the space between two mating surfaces, typically held together by bolts. Function: It creates a seal by being compressed between two stationary parts (like pipe flanges). Common Types: Spiral Wound Gaskets, Ring Type Joints (RTJ), and cut sheet gaskets. Best For: Static applications where the two surfaces do not move relative to each other. 2. What Is an O-Ring? (The Versatile Performer) An O-ring is a loop of elastomer (rubber) or metal with a round cross-section. It sits inside a designated groove and is compressed to create a seal. Function: It can seal against high pressure in both static (stationary) and dynamic (moving) applications. Common Types: NBR, Viton, EPDM, and Metal O-Rings. Best For: Hydraulic cylinders, pump shafts, and precise static grooves. The Key Differences: Gaskets vs O-Rings When deciding between Gaskets vs O-Rings, the choice usually comes down to three factors: Motion, Pressure, and Flange Design. A. Static vs. Dynamic Motion This is the biggest differentiator. Gaskets are almost exclusively used for static seals. If the two surfaces move or vibrate significantly, a standard gasket may tear or lose compression. O-Rings excel in dynamic seals. If you have a piston moving inside a cylinder or a rotating shaft, an O-ring (or dynamic seal) is required because it can handle the friction and motion. B. Pressure Handling In the comparison of Gaskets vs O-Rings, gaskets often win in heavy industrial piping. Gaskets (specifically RTJs): Designed for extreme pressure (up to 20,000 PSI). The harder you bolt the flange, the tighter the seal. O-Rings: Can handle high pressure, but they require backup rings to prevent “extrusion” (where the rubber is blown out of the gap). C. Surface Requirements Gaskets are forgiving. They can seal rougher, uneven flange surfaces because the gasket material deforms to fill the imperfections. O-Rings require precision. The groove must be machined to exact tolerances. If the surface is rough, the O-ring will suffer from abrasion and leak. Selection Guide: Which Should You Choose? To settle the Gaskets vs O-Rings debate for your specific project, ask these questions: Is there movement? Yes (Shafts, Pistons) – Choose an O-Ring. No (Pipe Flanges, Valve Bonnets) – Choose a Gasket. What is the connection type? Flat Flanges – Gasket (Spiral Wound or RTJ). Grooved Housing – O-Ring. What is the Temperature? Extreme Heat (>500°C)? $rightarrow$ You need a Metal RTJ Gasket or a Metal O-Ring (Elastomers will melt). Conclusion Ultimately, the choice of Gaskets vs O-Rings isn’t about which is “better”—it is about which fits the geometry of your equipment. If you are sealing a heavy-duty pipe flange in an oil refinery, you need an ADYAA Ring Type Joint. If you are sealing a hydraulic actuator, you need an ADYAA O-Ring. We stock both, ensuring you never have to compromise on seal quality. Need help specifying the right seal? Explore Our Gaskets & O-Rings Collection Contact our technical team for advice. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →

The Role of Sealing in Preventing Leakage & Safety Hazards

The Role of Sealing in Preventing Leakage and Safety Hazards A leak is rarely just a “drip.” In a chemical plant, a leak poses a significant risk of toxic exposure. In an oil refinery, there is a potential fire. In a high-pressure steam line, it is an explosion hazard. While pumps and reactors get the most attention during safety audits, the role of sealing in preventing leakage is arguably the most critical factor for maintaining facility integrity. It is the invisible shield that keeps your processes contained and your workforce safe. ADYAA understands that gaskets and seals are not just consumables; they are safety devices. In this guide, we explore how high-performance sealing mitigates catastrophic risks. Sealing Solutions for HSE Managers, Maintenance Leads, Reliability Engineers. The Real Cost of Leakage Leakage is often categorized into two types: visible leakage (drips and sprays) and fugitive emissions (invisible gas release). Both pose severe threats: Fire and Explosion: In the Oil & Gas sector, flammable hydrocarbons escaping from a failed flange gasket can be ignited by a single spark. Toxic Exposure: Leaking seals in chemical processing can release hazardous fumes (like chlorine or ammonia), endangering workers’ lungs and skin. Environmental Contamination: Seeping chemicals can contaminate groundwater, leading to massive EPA fines. Understanding the role of sealing in preventing leakage allows plant managers to address these risks before they become accidents. How Advanced Sealing Prevents Hazards Preventing these outcomes requires selecting the right seal for the specific hazard. Standard rubber O-rings often fail under extreme stress. Here is how specialized ADYAA sealing products fulfill the vital role of sealing in preventing leakage across different applications. 1. Controlling Extreme Pressure (The RTJ Solution) When pressures climb above 2,000 PSI, standard flat gaskets can blow out. The Solution: Ring Type Joint (RTJ) Gaskets. How it Works: Used heavily in the Oil & Gas industry, RTJs (like the Type R, RX, and BX) sit in a machined groove. The RX and BX styles are “pressure-energized,” meaning internal pressure pushes the gasket tighter against the flange. This mechanism highlights the active role of sealing in preventing leakage during dangerous pressure spikes. 2. Handling Extreme Temperatures In cryogenic applications (LNG) or superheated steam systems, elastomers become brittle and crack, leading to immediate failure. The Solution: Metal O-Rings and Lens Rings. How it Works: Made from heavy-duty alloys, Metal O-Rings and Lens Rings withstand temperatures that would melt rubber. They provide a high-pressure metal-to-metal seal, ensuring that even if the facility faces a fire, the seal remains intact. 3. Chemical Resistance Many industrial fluids are corrosive enough to eat through standard seals. The Solution: Spring Energized Seals and Bonded Seals. How it Works: By using high-grade polymers (like PTFE) energized by a corrosion-resistant spring, these seals maintain contact with the sealing surface even if the polymer degrades slightly. This confirms the role of sealing in preventing leakage of toxic chemicals that could otherwise dissolve standard gaskets. Why Seals Fail (And How to Stop It) Even the best gasket will leak if applied incorrectly. The three most common causes of sealing failure are: Incorrect Material Selection: Using a standard NBR O-ring in a high-temperature acid line. Improper Installation: Uneven bolt torque on a flange can crush a gasket or leave gaps. Reusing Disposable Seals: Many metallic gaskets (like RTJs) deform to create a seal and cannot be reused. Protect Your Workforce with ADYAA Safety is not a place to cut corners. Whether you require Weld Ring Gaskets for a permanent seal or Backup Rings for hydraulics, ADYAA has the engineering expertise to specify the correct component. We supply sealing products designed to Australian and International standards. By prioritizing the role of sealing in preventing leakage, you ensure your plant stays compliant, efficient, and accident-free. Is your facility fully protected? Browse Our Range of RTJ Gaskets & Metal Seals Contact ADYAA for a Sealing Safety Assessment. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →

What Is Industrial Sealing? Importance, Types & Benefits

What Is Industrial Sealing and Why Is It Important? In a massive refinery or a high-pressure mining plant, the most critical component often isn’t the largest pump or the tallest reactor—it’s the smallest seal. Industrial sealing is the unsung hero of process integrity. Whether it is a Ring Type Joint (RTJ) gasket in an oil pipeline or a simple O-ring in a hydraulic cylinder, seals are the barrier between a safe, efficient operation and a catastrophic failure. We specialize in high-performance sealing solutions for Australia’s toughest environments. In this guide, we break down what industrial sealing actually is, why it is critical for your bottom line, and the different types you need to know about. Industrial Sealing Solutions for Maintenance Managers, Process Engineers and Procurement Officers in Oil & Gas/Mining. What Is Industrial Sealing? At its core, industrial sealing is the technology used to block the passage of fluids (liquids or gases) through the gap between two joined surfaces. It serves two primary functions: Containment: Keeping the internal media (oil, steam, acid) inside the system. Exclusion: Keeping external contaminants (dust, dirt, moisture) outside the system. While this sounds simple, the challenge lies in the conditions. Industrial seals must maintain this barrier while enduring extreme temperatures (from cryogenic -196°C to scorching +1000°C), massive pressures (up to 20,000 PSI), and aggressive chemical corrosion. Why Is Industrial Sealing Important? You might view seals as cheap consumables, but their failure can cost millions. Here is why investing in quality sealing (like ADYAA’s RX Rings or Spiral Wound Gaskets) is non-negotiable. 1. Safety and Hazard Prevention The most immediate importance of sealing is human safety. In industries like Oil & Gas, a leaking flange isn’t just a mess; it’s a fire hazard or a toxic cloud. Proper sealing ensures that volatile organic compounds (VOCs) and dangerous chemicals stay contained, protecting your workforce from exposure and explosions. 2. Operational Efficiency A system that leaks pressure is a system that bleeds money. Pneumatic systems: Leaking air forces compressors to work harder, driving up electricity bills. Hydraulic systems: Fluid loss results in sluggish machinery and reduced force. High-quality seals ensure your equipment runs at peak parameter settings without wasting energy. 3. Environmental Compliance Australia has strict environmental regulations regarding emissions and ground contamination. A reliable sealing system helps you meet EPA standards by preventing “fugitive emissions”—the slow, invisible leaks of gas from valves and flanges that can lead to heavy fines. 4. Equipment Longevity Seals act as the first line of defense for your expensive assets. For example, a Spring-Energized Seal or a Polymer Bellow protects internal bearings and shafts from grit and corrosion. If the seal fails, the contaminant enters, and the machine destroys itself from the inside out. Types of Industrial Sealing Solutions Not all seals are created equal. Depending on your application, you will generally rely on one of these categories: A. Static Seals (Gaskets) These are used between two stationary surfaces, such as pipe flanges. RTJ Gaskets (Ring Type Joints): Metal gaskets (Oval, Octagonal, RX, BX) designed for high-pressure/high-temperature applications. They form a metal-to-metal seal ideal for the Oil & Gas industry. Spiral Wound Gaskets: A mix of metal winding and soft filler (graphite/PTFE), offering excellent recovery for fluctuating temperatures. B. Dynamic Seals These seals are between parts that move relative to each other (like a piston rod or a rotating shaft). Spring-Energized Seals: Used when standard elastomers fail. A spring ensures constant contact even when the polymer seal wears down. Packing: Soft braided material compressed around a shaft to prevent leakage in pumps and valves. C. O-Rings The most common seal type. These donut-shaped loops sit in a groove and compress to block fluid. Elastomeric: NBR, Viton, or EPDM for standard uses. Metal O-Rings: Used by ADYAA for extreme environments (aerospace, cryogenics) where rubber would melt or shatter. Summary: Don’t Let a Leak Stop Your Plant A seal might cost $50, but it protects a $500,000 pump and ensures the safety of everyone on site. Whether you need standard Lens Rings for steam lines or custom CNC-machined sealing components, quality matters. ADYAA supplies a full range of gaskets, O-rings, and custom seals engineered for the Australian industry. Need help selecting the right material for your chemical plant? View Our Full Range of Sealing Solutions. Contact our engineers for a consultation. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →

What is a Rupture Disc? Full Guide to Types & Applications

What is a Rupture Disc? A Full Guide (How They Work, Characteristics, & Uses) In the high-stakes world of industrial processing, pressure is a constant threat. If a pipe gets blocked or a chemical reaction runs out of control, pressure can build up in seconds, turning a steel tank into a potential bomb. To prevent this, most plants rely on safety valves. But valves have moving parts. They can seize, leak, or react too slowly to a sudden spike. Enter the Rupture Disc (also known as a Bursting Disc). It is the “airbag” of the process world—a simple, non-reclosing device that sacrifices itself to save your equipment. Once it activates, it’s gone, but your plant is safe. ADYAA supplies and distributes Rupture Discs in Australia, providing critical safety devices to local mining, oil & gas, and manufacturing industries. In this full guide, we will break down exactly what a Rupture Disc is, how it works, and why it might be the most important piece of metal in your facility. 1. What is a Rupture Disc? A Rupture Disc is a pressure relief device that consists of a thin, calibrated metal foil (the membrane) held between two metal holders. It is designed to be the “weakest link” in your pressure vessel. When the pressure inside the system hits a specific limit (the Burst Pressure), the disc physically tears open, allowing fluid or gas to escape instantly and relieving the pressure. Unlike a safety valve, which opens and then closes again, a Rupture Disc is a non-reclosing device. Once it bursts, it must be replaced. 2. How Do They Work? The mechanism is pure physics. Normal Operation: The disc acts as a solid seal, keeping the process fluid inside the pipe. Pressure Rise: As pressure builds, the metal foil begins to stress. Burst Point: When the pressure differential across the disc exceeds its tensile strength (the set pressure), the metal fails. Relief: The disc opens fully (in milliseconds), creating an unrestricted path for the gas or liquid to vent out safely. 3. Key Characteristics & Types Not all discs are the same. Engineers select a Rupture Disc based on specific characteristics: A. Forward Acting (Tension Loaded) How it works: The pressure pushes against the concave (hollow) side of the dome. The metal stretches until it snaps, like blowing up a balloon until it pops. Best for: Lower operating pressures and static loads. B. Reverse Acting (Compression Loaded) How it works: The pressure pushes against the convex (bulging) side of the dome. When the pressure hits the limit, the dome “snaps” through (inverts) and is sliced open by a knife blade or scored lines on the metal. Best for: High operating pressures (up to 95% of burst pressure) and cycling conditions. C. Materials Discs are made from exotic materials to resist corrosion and ensure precision. Common materials include Stainless Steel (316L), Inconel, Monel, Nickel, and Graphite. 4. Applications & Use Cases Where do you actually install a Rupture Disc? 1. As a Primary Relief Device Used on vessels where a valve is too expensive, too slow, or simply unnecessary. Example: A chemical reactor where a runaway reaction creates a pressure spike faster than a valve can open. 2. Upstream of a Safety Valve (The “Bodyguard”) This is the most common industrial use. The disc is installed before a Safety Relief Valve. Why? It seals the expensive valve off from corrosive chemicals or sticky fluids that would gum up the valve internals. If the pressure spikes, the disc bursts, and then the valve opens. 3. Downstream of a Safety Valve Installed on the outlet to prevent corrosive vapors from the header system entering the valve from the back. 5. Advantages of Using a Rupture Disc Why choose a disc over a valve? Zero Leakage: It is a solid metal seal. Unlike valves, which can “simmer” or leak slightly, a disc is bubble-tight. Essential for toxic or expensive gases. Instant Response: There is no spring to compress or piston to move. It opens in milliseconds. Cost-Effective: A disc is significantly cheaper than a high-performance safety valve. Low Maintenance: It has no moving parts. No lubrication or adjustment is needed. 6. FAQ: People Also Ask Here are the answers to the most common questions about Rupture Discs. What happens if a disc ruptures? When a disc ruptures, it creates an open path for the process fluid to escape. The system pressure drops rapidly. However, because the seal is broken, the process fluid will continue to vent until the system is shut down or isolated. You must stop production to replace the disc. What is the life of a rupture disc? A Rupture Disc does not last forever. Fatigue from pressure cycling (going up and down) eventually weakens the metal. Recommendation: Most manufacturers recommend replacing discs once a year during preventative maintenance, even if they haven’t burst. Harsh conditions: In corrosive or high-cycling environments, they may need replacement every 6 months. Where is the rupture disc located? They are typically located directly on the pressure vessel nozzle or in the piping immediately before a Safety Relief Valve. They are mounted inside a specialized Safety Head (holder) that is bolted between two pipe flanges. What does a rupture disc look like? It looks like a round, slightly domed metal plate, usually with a metal tag handle sticking out. The tag contains vital info like the Burst Pressure, Temperature Rating, and Flow Direction arrow. Note: Never paint over the disc or the tag! Conclusion: A Small Device with a Big Job A Rupture Disc is often the last line of defense between safe operation and a major incident. It is simple, reliable, and absolutely critical. Whether you need to protect a storage tank from vacuum collapse or shield a safety valve from corrosion, choosing the right disc requires expert sizing. ADYAA supplies and distributes Rupture Discs in Australia, offering high-precision safety heads tailored to your plant’s unique hazards. Ready to secure your pressure systems? Explore ADYAA Rupture Discs