Why Dew Point Sensors Are Critical in Industrial Air and...

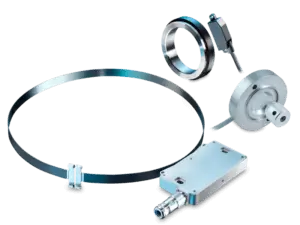

Encoders play a key role in tracking movement, speed, and direction with high accuracy. Ideal for automation, robotics, and industrial machinery, they convert mechanical motion into digital signals ensuring smooth operation and reliable performance.

Get application-specific solutions from our technical specialists.

Enjoy responsive service backed by global ABB technology.

Simplify meeting and documenting environmental standards.

Encoders deliver accurate speed, direction, and position data essential for robotics, automation, and industrial systems. Optimize performance with reliable motion tracking and seamless integration.

Available with magnetic or optical sensing to match diverse application needs.

Multiple signal interfaces and shaft options ensure seamless integration.

Compact housings from 28 mm to 58 mm, suitable for space-critical designs.

Designed for quick installation and reliable performance in industrial environments.

Fine incremental or absolute counts for precise motion.

Fast update rates for high-speed servo loops.

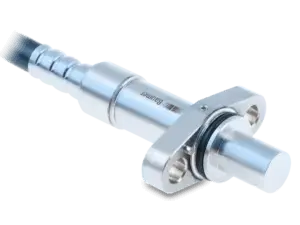

Durable bearings, shafts, and IP-rated housings resist vibration.

TTL/HTL, Sin/Cos, SSI, BiSS, and fieldbus outputs for easy integration.

LongLife HeavyDuty design ensures maximum reliability and long service life.

Dual-bearing construction for stability in demanding industrial use.

Silver track commutator maintains consistently low contact resistance.

Special brush system delivers wear-resistant, long-lasting performance even in extreme conditions.

Customizable settings: pulse count, HTL/TTL level, sequence, and zero pulse.

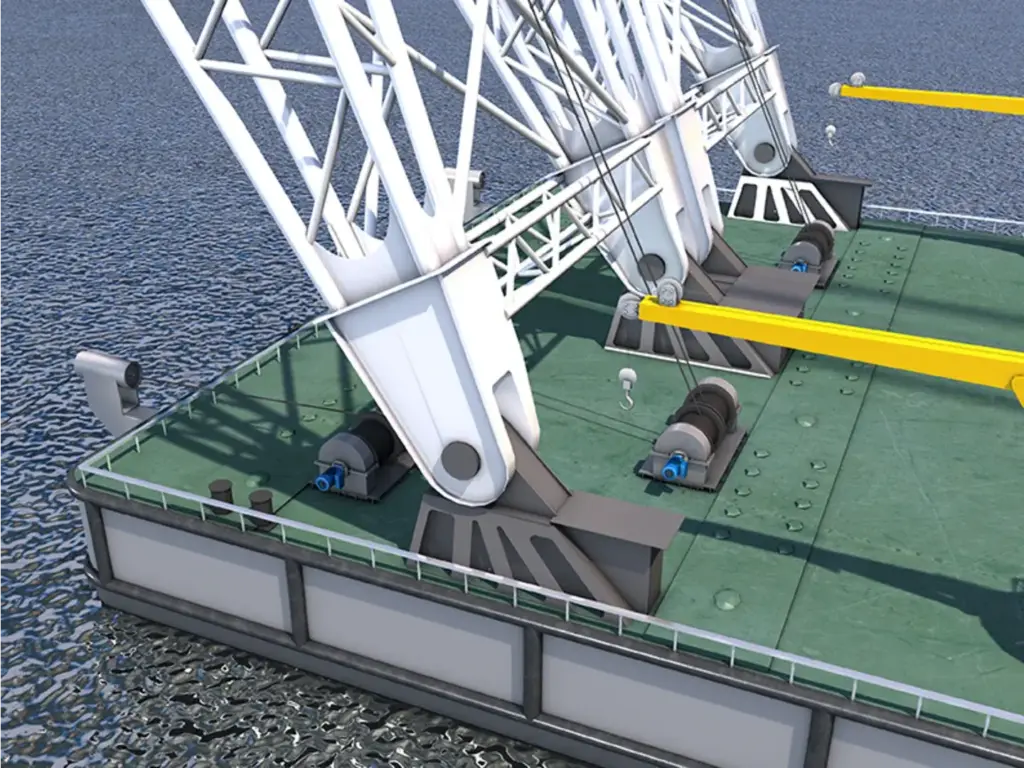

Designed for end users, OEMs, wholesalers, and system integrators.

Suitable for a wide range of automation and motion control applications.

Helps reduce downtime, spare part variety, and storage costs.

Support PROFINET, EtherCAT, EtherNet/IP, and OPC UA on request.

Industry 4.0 & IIoT ready, ensuring future-proof integration.

Enable high-precision machine control in real time.

Flexible operating modes and data access tailored to application needs.

Stay ahead with technology built for efficiency and reliability.

Why Dew Point Sensors Are Critical in Industrial Air and...

Understanding Thermowells and Their Role in Process Instrumentation In the...

5 Signs Your Equipment Needs Calibration Now In a perfect...

Coating Thickness Inspection for Improved Process Reliability In industrial manufacturing,...

ADYAA’s encoders lock in repeatable precision for flawless performance. Book Now.

Visit ADYAA ENGINEERING

Unit 3, 5 Murphy Street

O’Connor, Perth WA 6163

Australia

Contact: