Tank Protection Valve Full Guide: Types, Benefits & Selection

Tank Protection Valve Full Guide: Types, Benefits & Selection A bulk storage tank is not just a static metal box; it is a breathing lung. As temperatures rise during the day, the liquid inside expands and vapors build up (Exhalation). At night, or when pumping liquid out, the tank cools and creates a vacuum (Inhalation). If you block this breathing process, the physics are unforgiving: the tank will either rupture from overpressure or crumple inward like a crushed soda can. To prevent this catastrophe, engineers rely on a critical device: the Tank Protection Valve. ADYAA supplies, we specialize in low-pressure safety systems that keep Australian storage terminals compliant and safe. In this Tank Protection Valve full guide, we will explore what these valves are, the different types available, and how to assess which one is right for your facility. 1. What is a Tank Protection Valve? A Tank Protection Valve (often called a Breather Valve or PVRV) is a self-acting safety device mounted on the roof of a storage tank. Its primary job is to control the pressure inside the tank. Overpressure Relief: When internal pressure exceeds a set limit (e.g., due to filling or heat), the valve lifts to vent gas out. Vacuum Relief: When internal pressure drops (e.g., due to draining or cooling), the valve opens to let air (or inert gas) in. Unlike standard safety valves which handle high pressure (bars), a Tank Protection Valve operates at very low pressures (millibars or inches of water column). 2. Types of Tank Protection Valves Not all tanks breathe the same way. Depending on your stored product (flammable, toxic, or harmless), you need specific equipment. A. Pressure / Vacuum Relief Valve (PVRV) This is the standard “Breather Valve.” It handles both overpressure and vacuum in a single unit. Use Case: Standard diesel, water, or oil storage tanks. It reduces vapor loss by keeping the tank sealed until necessary. B. Emergency Relief Vent (ERV) A PVRV handles daily breathing, but what if there is a fire surrounding the tank? The liquid boils rapidly, creating massive vapor volume that a small PVRV cannot handle. Function: An ERV is a heavy weighted hatch that flips open only during emergency overpressure to prevent the tank from exploding. C. Tank Blanketing Valve (Pad Valve) For flammable or sensitive liquids (like methanol or food oils), you don’t want oxygen entering the tank. Function: Instead of letting in air, this valve injects an inert gas (usually Nitrogen) to fill the empty space. This prevents oxidation and eliminates the risk of an internal explosion. 3. Key Benefits (The Value of Protection) Why invest in high-quality ADYAA breathing valves instead of a simple open vent? 1. Safety & Structural Integrity The most obvious benefit is preventing tank failure. A collapsed tank can cost hundreds of thousands of dollars to replace, not to mention the environmental cleanup costs. 2. Reduced Vapor Loss (Cost Savings) An open vent lets expensive products evaporate into the sky 24/7. A Tank Protection Valve keeps the tank sealed 95% of the time, only opening when absolutely necessary. This retains the product and saves money. 3. Environmental Compliance Strict EPA and Australian environmental laws limit the amount of Volatile Organic Compounds (VOCs) you can release. A tight-sealing valve significantly reduces your emissions footprint. 4. How is a Tank Protection Valve Assessed? (Selection Criteria) Selecting the right valve is not guesswork; it is a calculation based on API 2000 standards. When assessing a valve for your tank, engineers look at three main factors: A. Set Pressure & Vacuum You must know the Maximum Allowable Working Pressure (MAWP) of your tank. The Rule: The Tank Protection Valve must open below the tank’s failure point but above the normal operating pressure to avoid constant venting. B. Flow Capacity (Breathing Requirement) How fast are you filling or emptying the tank? If you pump liquid out at 1,000 Liters/minute, the valve must be able to suck in air at that same rate (plus thermal contraction). If the valve is too small, you pull a vacuum and buckle the tank. C. Material Compatibility Is the fluid corrosive? For water, Aluminum is fine. For acids or sour gas, you need 316 Stainless Steel or Hastelloy internals to prevent the pallet from sticking. 5. Why Choose ADYAA for Tank Protection? In the harsh Australian sun, seals dry out and pallets get stuck. You need equipment built for our climate. ADYAA supplies and distributes robust Tank Protection Valves designed for longevity and precision. Whether you need a simple breather for a water tank or a complex nitrogen blanketing system for a chemical reactor, we have the stock and the engineering expertise to support you. Don’t leave your storage assets exposed. Explore ADYAA Tank Protection Valves View Emergency Vents & Flame Arrestors Contact us. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →

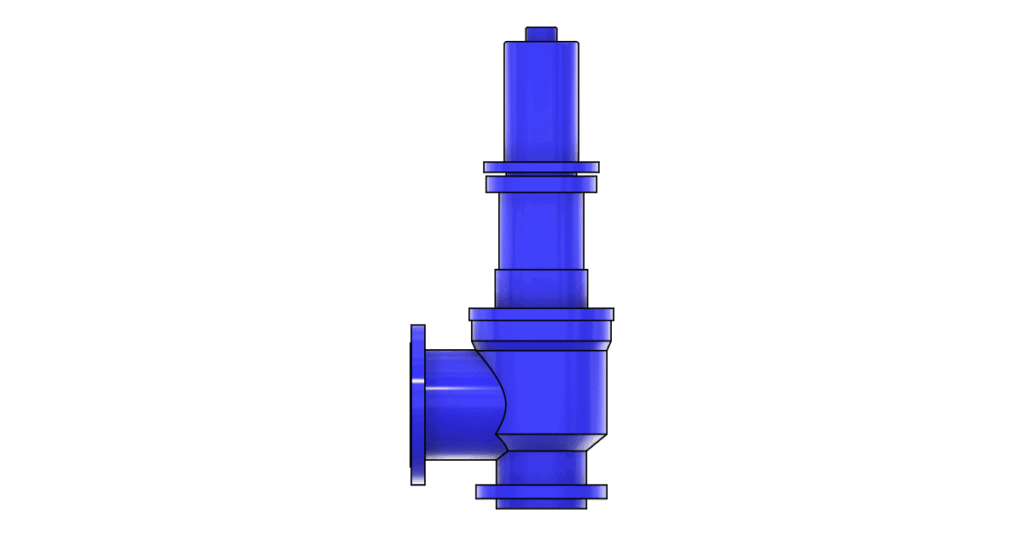

Safety Relief Valve vs Pressure Relief Valve: The Key Differences

Safety Relief Valve vs Pressure Relief Valve: The Key Differences In the world of industrial process control, terms often get thrown around loosely. You’ll frequently hear engineers say “Relief Valve” when they mean “Safety Valve,” and vice versa. But if you are the one signing off on a purchase order—or worse, the one responsible for plant safety during an audit—you know that Safety Relief Valve vs Pressure Relief Valve isn’t just a semantic argument. It is a critical engineering distinction. Choosing the wrong device for your medium (Gas vs. Liquid) doesn’t just mean your system will be inefficient; it means it could be dangerous. A valve designed to “pop” open for steam might hammer itself to destruction if used on water. ADYAA supplies comprehensive pressure relief systems to industries worldwide. In this guide, we are clearing up the confusion so you can specify the right valve for your line with confidence. Safety Relief Valve and Pressure Relief Valve for Plant Engineers, Maintenance Managers, and Safety Officers. 1. What is a Safety Valve? (The “Pop” Action) A Safety Valve is a safety device designed to open rapidly and fully the moment the pressure hits the set limit. Think of a balloon popping—it doesn’t release air slowly; it releases it all at once. Primary Use: Compressible fluids (Steam, Air, Gas). Mechanism: It relies on the kinetic energy of the expanding gas to lift the valve disc instantly to 100% open. Why use it? Gases expand rapidly. If a boiler is over-pressurizing, you need to vent a massive volume of gas immediately to prevent an explosion. A slow-opening valve would be too dangerous in this scenario. 2. What is a Pressure Relief Valve? (The “Gradual” Action) A Pressure Relief Valve (PRV) is designed to open gradually, proportional to the increase in pressure. Think of turning on a kitchen tap—the more you turn it, the more water flows. If the pressure is 10% over the limit, the valve opens 10%. If the pressure drops, the valve slowly closes. Key Functions: Proportional Control: It modulates the opening to release only as much fluid as necessary to bring the pressure back down. Protection: It acts as a limit on the maximum pressure in a hydraulic or liquid circuit. Primary Benefits: Prevents Water Hammer: Because it opens and closes gradually, it avoids the sudden shockwaves (hydraulic shock) that destroy pipes and pumps. System Stability: It maintains a steady pressure in the line without causing the massive pressure drops that a Safety Valve would cause. Liquid Compatibility: Specifically engineered for Non-Compressible fluids like Water, Oil, and Hydraulic Fluid. 3. Safety Relief Valve vs Pressure Relief Valve: The Comparison To decide which one you need, you simply have to look at how the valve reacts to pressure. The Core Difference: “Pop” vs. “Open” Safety Valve: Snaps open to 100% lift instantly. (Digital: On/Off). Relief Valve: Opens slowly as pressure builds. (Analog: Proportional). Comparison Table: PSV vs. PRV Save this cheat sheet for your next planning meeting. Feature Safety Valve Pressure Relief Valve Action Rapid “Pop” Opening (Snap Action) Gradual Opening (Modulating) Primary Medium Gas, Steam, Air (Compressible) Water, Oil, Chemicals (Non-Compressible) Goal Prevent Catastrophic Failure (Explosion) Control Pressure / Protect Equipment Reset Pressure Closes well below set pressure (Blowdown) Closes near set pressure Common Use Boilers, Steam Drums, Air Receivers Hydraulic Lines, Pump Discharge, Lube Systems 4. What is a “Safety Relief Valve”? (The Hybrid) Here is where it gets tricky. You will often see the term Safety Relief Valve (SRV). An SRV is a versatile specialized valve that can function as either a Safety Valve or a Relief Valve, depending on the application. On Gas/Steam: It “pops” open. On Liquid: It opens in proportion to the pressure rise. ADYAA Insight: Many modern plants standardize on Safety Relief Valves to reduce inventory complexity, but you must ensure the trim and seal materials are compatible with your specific process fluid. 5. Beyond the Valve: ADYAA Protection Systems Sometimes, a valve isn’t the right solution—or it isn’t enough on its own. At ADYAA, we often recommend a layered approach to safety. Rupture Discs: A non-reclosing metal foil that bursts at a set pressure. Used as a fail-safe backup or for viscous fluids that would gum up a valve spring. Tank Protection (Vents): Breather valves that manage both venting and vacuum to prevent storage tanks from imploding during draining. Flame Arrestors: Essential for fuel lines to stop external fires from traveling back down the pipe into the tank. 6. How to Select the Right ADYAA Valve When you contact ADYAA for a relief system, we will guide you through three main questions: What is the State of Matter? Gas/Steam $rightarrow$ You likely need a Safety Valve. Liquid $rightarrow$ You likely need a Pressure Relief Valve. What is the Set Pressure? We need to know the exact point you want the valve to lift. What is the “Back Pressure”? Is the valve venting to the atmosphere (open air) or into a closed pipe system? Back pressure in pipes can affect when the valve opens. Conclusion: Don’t Guess with Safety The difference between Safety Relief Valve vs Pressure Relief Valve is the difference between a controlled release and a catastrophic pipe failure. Whether you need a Rupture Disc for a chemical reactor or a standard Pressure Relief Valve for a hydraulic pump, getting the specs right is non-negotiable. ADYAA offers pressure relief systems designed for reliable performance in harsh industrial environments. Need to secure your pressure vessels? Explore ADYAA Safety Valves & Rupture Discs View Tank Protection & Flame Arrestors Contact our Engineering Team for a Sizing Consultation. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More →

RTD vs Thermocouple: The Complete Guide to Industrial Sensors

RTD vs. Thermocouple: The Complete Guide to Industrial Temperature Sensors RTD vs. Thermocouple: Which Sensor is Right for Your Application? In industrial automation, temperature is not just a number, it’s the heartbeat of your process. Whether you are pasteurizing milk, refining oil, or monitoring exhaust gas, your control system is only as good as the sensor feeding it data. But when you need to spec a new project, you face the classic engineering debate: RTD vs. Thermocouple. To the naked eye, they look identical. But inside the metal sheath, they operate on completely different physics. Choosing the wrong one can lead to “drifting” readings, frequent failures from vibration, or unnecessary costs. ADYAA supplies RTD and thermocouples to all industries across Australia. In this guide, we break down the technical differences to help you choose the right tool for the job. RTD and Thermocouples for Engineers, Maintenance Managers, and Procurement. What is the Difference Between RTD and Thermocouple? Before we compare them, we need to define what they actually are. What is an RTD Sensor? (Resistance Temperature Detector) Think of the RTD as the “Precision Instrument.” It works on a physical principle: as metal gets hotter, it becomes harder for electricity to pass through it (resistance increases). By measuring this resistance, we calculate the exact temperature. Most Common Type: Pt100 (Platinum element, 100 ohms at 0°C). Key Characteristic: High accuracy and long-term stability. What is a Thermocouple? (T/C) Think of the Thermocouple as the “Rugged Workhorse.” It works on the Seebeck Effect. Two different metal wires are joined together at a tip. When that tip heats up, it generates a tiny voltage signal. Most Common Type: Type K (Nickel-Chromium). Key Characteristic: Extreme durability and high-heat handling. Comparison: RTD vs. Thermocouple Accuracy & Range When choosing between these two, the decision usually comes down to four critical factors. 1. Temperature Range: How Hot Does It Get? This is your primary filter. RTD Range (-200°C to +850°C): This covers 90% of industrial applications, including Food & Beverage, Pharma, and HVAC. Thermocouple Range (-200°C to +2300°C): If you are working with fire—blast furnaces, kilns, or jet engines—you must use a Thermocouple. A standard Type K handles 1250°C easily. 2. Accuracy: Do You Need Precision? RTD Accuracy: If your process needs to be within ±0.1°C (like dairy or chemical dosing), the RTD is the winner. They are linear, stable, and don’t “drift” much over time. Thermocouple Accuracy: They are generally less precise, typically drifting by ±1.0°C to ±2.0°C. Over time, the internal wires can degrade, causing the reading to shift. 3. Response Time: How Fast Does It React? Thermocouples: Because the measuring point is just a tiny welded bead, they react almost instantly to temperature spikes. RTDs: The platinum element is often encased in ceramic or glass, which adds mass. This means they take a few seconds longer to register a temperature change. 4. Durability: Handling Vibration Thermocouples: Being essentially solid wire, they are incredibly tough. They are the best choice for high-vibration environments like engines, compressors, and crushers. RTDs: The internal element is delicate. Heavy vibration can break the fine platinum wires inside, leading to sensor failure. Comparison Chart: Pt100 vs. Type K Quick reference guide for Engineers. Feature RTD (Pt100) Thermocouple (Type K) Best Application Precision Control (Food, Pharma) High Heat & Vibration (Furnace, Mining) Temp Limit Up to 850°C Up to 1250°C+ Accuracy High (±0.15°C) Medium (±1.1°C – ±2.2°C) Response Time Slower Fast Drift / Stability Very Stable Prone to drift over time Cost Moderate Low When Should You Use an RTD? Choose an ADYAA RTD if: Accuracy is critical: Your process requires tight control (e.g., pasteurization, labs). Temperature is moderate: The process is below 600°C. Stability matters: You want a “set and forget” sensor that won’t drift over the years. When Should You Use a Thermocouple? Choose an ADYAA Thermocouple if: Heat is extreme: You are measuring over 850°C. Vibration is high: The sensor is mounted on a heavy engine or vibrating machine. Budget is tight: You need a simple, low-cost solution for general monitoring. Speed is key: You need to catch rapid temperature spikes instantly. Conclusion: Making the Right Choice There is no “bad” sensor, only the wrong application. Putting a delicate RTD in a blast furnace will destroy it. Putting a generic Thermocouple in a vaccine fridge will compromise your data. ADYAA helps you engineer the loop. From custom-length thermocouples to sanitary RTDs, we have the stock and the expertise to get your process running right. Need help selecting the right sensor? Explore ADYAA Temperature Sensors. Chat with an ADYAA Engineer today. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →

What Is Industrial Instrumentation? A Guide To Smarter Process Control

What Is Industrial Instrumentation? A Guide To Smarter Process Control Industrial instrumentation is the science of measurement and control. It encompasses the vast array of devices, sensors, and systems used to monitor, measure, and regulate physical variables like pressure, temperature, level, and flow within industrial processes. Think of it as the central nervous system for a factory or plant; it provides the critical real-time data needed to make informed decisions, ensuring everything operates safely, efficiently, and consistently. Without accurate instrumentation, processes would be blind, unreliable, and potentially dangerous. Key Aspects of Instrumentation: The Big Four Measurements Four fundamental variables, expertly managed by instrumentation, are at the heart of most processes. Pressure: The force applied by a gas or liquid on a surface. It’s crucial for containing energy within systems. Example: A pressure gauge on a compressed air tank ensures it doesn’t exceed its maximum safe working pressure, preventing a catastrophic rupture. Level: The height of a substance (liquid or solid) in a vessel, tank, or silo. It’s essential for inventory management and preventing overfills. Example: A level gauge on a fuel storage tank tells operators how much product is available, ensuring a facility doesn’t run out unexpectedly during a critical operation. Flow: The rate at which a fluid or gas moves through a pipe. It is key to managing material consumption and production rates. Example: A flow meter on a chemical injection skid precisely measures the exact amount of additive being mixed into a main product, guaranteeing the final mixture’s quality and consistency. Temperature: The degree of hotness or coldness in a system. It is vital for reaction control, safety, and product quality. Example: A temperature gauge in a brewery’s mash tun ensures the grains are held at the perfect temperature to activate enzymes, which is essential for converting starches into fermentable sugars. Benefits of Instrumentation: More Than Just Numbers Investing in high-quality instrumentation delivers tangible returns across your entire operation. Safety: This is the top priority. Instruments act as the first line of defense, preventing disasters like equipment over-pressurization, tank overfills, or overheating. Efficiency & Cost Savings: By providing precise data, instrumentation helps optimize resource use. You use exactly the amount of energy, water, or raw materials needed, reducing waste and lowering operational costs. Quality Control: Consistent processes create consistent products. Instrumentation ensures every batch meets the same specifications, protecting your brand’s reputation. Downtime: Predictive maintenance is powered by instrumentation. Small changes in vibration, temperature, or pressure can signal an impending failure, allowing you to schedule repairs before a costly, unplanned shutdown occurs. Why is precise instrumentation non-negotiable? The old adage is true: “You can’t control what you don’t measure.” Guessing leads to inefficiency, product waste, and risk. Instrumentation replaces guesswork with hard data, providing the visibility required to automate complex processes, protect multi-million dollar assets, and make strategic decisions that boost profitability. Examples of Instruments in Action: Oil & Gas: A pressure gauge on a wellhead monitor ensures extraction pressures are safe and optimal. Water Treatment: A pH sensor (a type of analytical instrument) constantly measures water acidity to ensure the correct dosage of treatment chemicals. Power Generation: A vibration monitor on a turbine shaft detects unusual oscillations, signaling the need for maintenance before a breakdown happens. Food & Beverage: A sanitary temperature indicator in a pasteurization line verifies that someone has heated milk to the required temperature to ensure it is safe for consumption. The Bottom Line Instrumentation is not an overhead cost; it is a foundational investment in the safety, intelligence, and profitability of your industrial operations. Choosing robust, accurate, and reliable instruments from a provider like ADYAA ensures your process control is in expert hands, giving you peace of mind and a clear competitive advantage. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Vision & Imaging Sensors Transform Automated Inspection Systems IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Gaskets vs O-Rings: Which Sealing Solution Is Right for You? Load More

What is a Safety Relief Valve? – The Complete Beginner’s Guide

What is a Safety Relief Valve? – The Complete Beginner’s Guide A Safety Relief Valve (SRV) is a vital protective component in industrial systems, designed to safeguard equipment, processes, and personnel from dangerous overpressure. Its function is to automatically discharge excess pressure from vessels, pipelines, or systems once a preset pressure level is exceeded, and then close again once normal conditions return. Purpose of a Safety Relief Valve The main role of an SRV is to avoid serious failures by venting surplus pressure. Overpressure can result from various causes, including process disturbances, thermal expansion, mechanical malfunction, or human error. In such cases, the SRV serves as the final layer of protection. How a Safety Relief Valve Works Most SRVs work using a spring-loaded or pilot-operated setup. Under typical conditions, the spring keeps the valve shut. If the system pressure rises above the set value, the force from the fluid overcomes the spring’s tension, lifting the valve disc to release the extra pressure. Once the pressure falls below the set point, the spring pushes the disc back into position, closing the valve and stopping the flow. Key Standards & Regulations Safety Relief Valves must comply with recognized international standards to ensure performance and safety. Commonly followed standards include: ASME Boiler and Pressure Vessel Code, Section VIII. API Standards 520 and 521 ISO 4126 – Pressure protection safety devices. Industries That Use Safety Relief Valves SRVs are commonly found in sectors where overpressure could cause significant hazards, such as: Oil and Gas Chemical Manufacturing Power Plants Pharmaceutical Production Food and Beverage Processing Why Safety Relief Valves are Important Without SRVs, overpressure incidents could lead to accidents, major equipment damage, operational downtime, and even loss of life. Selecting, installing, and maintaining the correct SRV is critical for safe and dependable operations. At Adyaa Engineering, we provide and service certified Safety Relief Valves that conform to international requirements and suit specific applications. Our specialists handle sizing, selection, and testing to ensure top-level safety and reliability. How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Vision & Imaging Sensors Transform Automated Inspection Systems IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Gaskets vs O-Rings: Which Sealing Solution Is Right for You? Load More