Why Dew Point Sensors Are Critical in Industrial Air and...

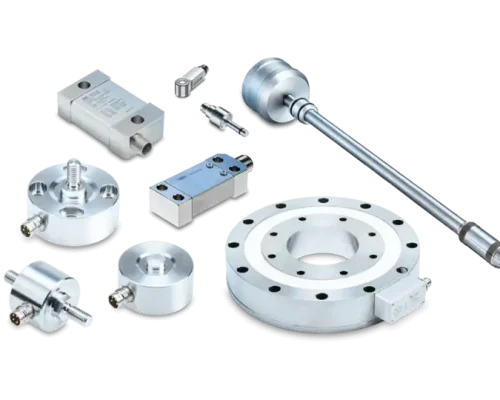

Force and load sensors often referred to as stress transducers, play a vital role in capturing mechanical strain and converting it into actionable data. These precision instruments are essential for performance optimization across industries, enabling systems to monitor weight, pressure, and tension in real time.

Get application-specific solutions from our technical specialists.

Enjoy responsive service backed by global ABB technology.

Simplify meeting and documenting environmental standards.

Built for resilience and engineered for precision, they’re essential for industries where every gram and Newton counts. Monitor mechanical strain and optimize performance with precision force and load sensors. Ideal for real-time weight tracking, structural safety, and smart .

Automotive Manufacturing: Force and strain sensors are used for crash testing, suspension analysis, and seat occupancy detection to ensure safety and performance.

Injection Molding: Cavity pressure sensors monitor internal mold pressure in real time, improving product consistency and reducing defects in plastic manufacturing.

Aerospace Engineering: Strain measurement in holes helps assess stress concentrations in aircraft components, ensuring structural integrity under extreme conditions.

Robotics and Automation: Force sensors enable precise grip control and collision detection in robotic arms and automated handling systems.

Civil and Structural Monitoring: Strain sensors are embedded in bridges, buildings, and tunnels to monitor load distribution and detect early signs of fatigue or failure.

Medical Devices: Load cells and miniature force sensors are used in prosthetics, surgical tools, and diagnostic equipment for accurate force feedback and control.

Stay ahead with technology built for efficiency and reliability.

Why Dew Point Sensors Are Critical in Industrial Air and...

Understanding Thermowells and Their Role in Process Instrumentation In the...

5 Signs Your Equipment Needs Calibration Now In a perfect...

Coating Thickness Inspection for Improved Process Reliability In industrial manufacturing,...

Adyaa’s sensors reveal the exact load so you can optimise performance. Buy Now.

Visit ADYAA ENGINEERING

Unit 3, 5 Murphy Street

O’Connor, Perth WA 6163

Australia

Contact: