When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

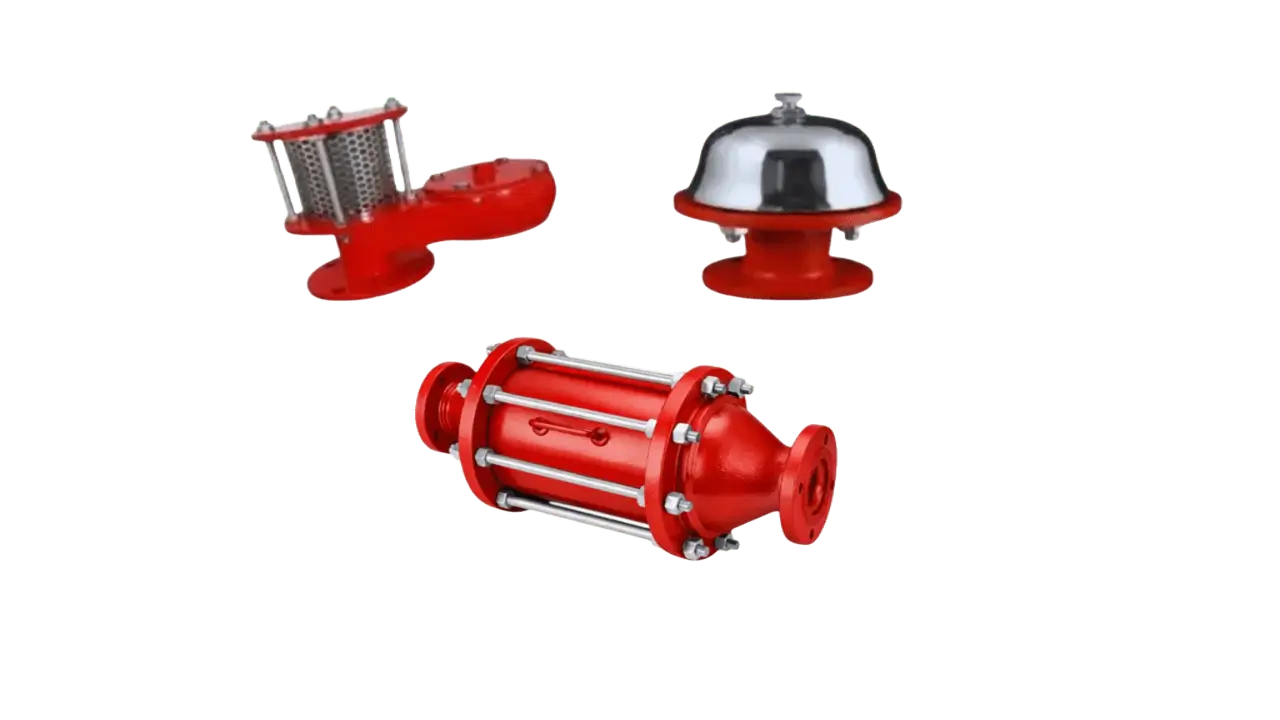

Don’t let a stray spark turn into a disaster. Without protection, fire can travel swiftly backward through pipes (flashback), risking your entire storage facility. Our devices act as a thermal barrier to extinguish flames instantly. They block the explosion path while allowing gas to flow, ensuring total plant safety. Shop Flame Arrestors from ADYAA.

Provides dependable overpressure protection to ensure the safety of equipment, personnel, and processes in all operating conditions.

Accurately responds to pressure variations, offering consistent relief and maintaining system stability under critical situations.

Built with high-quality stainless steel and corrosion-resistant materials for superior performance in harsh and demanding environments.

Available in a wide range of pressure ratings, sizes, and end connections to meet diverse industrial applications.

Meets international standards such as ASME, API, and PED, guaranteeing safe and compliant operation in all pressure systems.

Stay ahead with technology built for efficiency and reliability.

When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

Flange Sealing Solutions for High-Pressure Pipes: Zero Leakage Strategies In...

How to Select Pressure Relief Valves for Industrial Plants If...

How Rupture Discs Protect Pressure Systems from Catastrophic Failure In...

Secure your facility against explosions with our certified Flame Arrestors. Consult an Expert at ADYAA.

Visit ADYAA ENGINEERING

Unit 3, 5 Murphy Street

O’Connor, Perth WA 6163

Australia

Contact: