When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

Designed to withstand harsh environments, these switches offer flexible installation options and maintain reliable performance even under high temperature, pressure, and dusty conditions.

Engineered for steady performance with minimal maintenance.

Find the exact pressure range you need from our wide selection.

From vibrations to extreme temperatures.

Get personalized, hands-on assistance from our team.

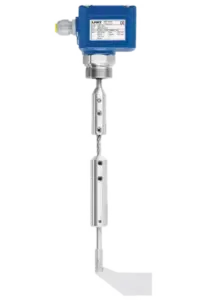

Rotary paddle switches provide dependable point level detection for bulk solids, ensuring safe and efficient operation across industries like cement, food, chemicals, and power generation.

Compact rotary paddle switch for bulk solids.

Ideal for small bins and tight spaces.

Handles moderate temperatures and pressures.

Suitable for powders and granules.

Flexible rope extension for tall silos.

Detects full or empty levels in bulk solids.

Operates in dusty and high-temp environments.

Easy to install in deep vessels.

Rigid tube extension for vertical mounting.

Withstands high temperatures and pressures.

Suitable for coarse or abrasive materials.

Offers stable level detection.

Reinforced rope for heavy-duty use.

Handles high mechanical stress.

Ideal for tall silos with dense materials.

Reliable in harsh conditions.

Side-mounted paddle for narrow spaces.

Compact design for small hoppers.

Works with fine to coarse solids.

Quick response and easy setup.

Adjustable sensitivity for varied materials.

Designed for medium-sized containers.

Performs well in dusty environments.

Simple installation and maintenance.

Heavy-duty switch for large silos.

Built for dense and abrasive materials.

Long-lasting in tough industrial settings.

Ideal for cement, sand, and gravel.

Explosion-proof for hazardous zones.

Certified for ATEX environments.

Safe detection in flammable areas.

Used in chemical and petrochemical plants.

Compact and versatile paddle switch.

Works with fine and granular solids.

Reliable in standard applications.

Easy to integrate into systems.

Rope extension for deep tank mounting.

Handles high temperature and pressure.

Ideal for full/empty detection.

Resistant to buildup and wear.

Durable rope for tough bulk materials.

Withstands high mechanical loads.

Accurate in extreme conditions.

Designed for long-term use.

Rigid tube for vertical installations.

Suitable for abrasive and hot materials.

Consistent level detection.

Ideal for cement and lime industries.

Ideal for compact industrial installations.

Perfect for low-volume material handling.

Ensures responsive and accurate detection.

Maintains performance in limited space environments.

High-performance switch for demanding tasks.

Built for large vessels and heavy loads.

Robust and long-lasting design.

Used in mining and heavy industry.

It accurately detects whether a container is full, empty, or needs refilling.

The device works well with a wide range of solid materials like powders and granules.

Its sturdy design allows it to operate under high temperatures and pressure.

You can install it in different ways, including compact, rope, or tube versions.

It performs reliably even in dusty or vibrating environments.

Some models are explosion-proof, making them safe for use in hazardous areas.

Cement Industry: Detects level of cement, sand, and gravel in silos.

Chemical Plants: Monitors powders and granules in process tanks.

Food & Beverage: Controls dry ingredients like flour and sugar.

Pharmaceuticals: Ensures accurate dosing of powders and excipients.

Plastic Industry: Tracks plastic pellets in storage and feed bins.

Power Plants: Manages coal and ash levels in fuel handling systems.

Point level measurement offers precise detection of material reaching a defined point inside tanks or silos, enabling seamless automation of filling and emptying processes while safeguarding against overflow and depletion to maintain operational efficiency.

Vibration level switch senses material presence using a vibrating probe interrupted by solids or liquids

Capacitive level switch detects material by measuring changes in capacitance near its sensing probe

Get the latest updates and insights on industrial instrumentation and process control.

When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

Flange Sealing Solutions for High-Pressure Pipes: Zero Leakage Strategies In...

How to Select Pressure Relief Valves for Industrial Plants If...

How Rupture Discs Protect Pressure Systems from Catastrophic Failure In...

Get the perfect Rotary Paddle Switch for your needs. Reach out to the ADYAA team for a personalized recommendation.

Visit ADYAA ENGINEERING

Unit 3, 5 Murphy Street

O’Connor, Perth WA 6163

Australia

Contact: