Every maintenance manager faces the same dilemma eventually. You have a critical audit coming up, or perhaps your process data looks slightly “off.” You know your instruments need attention, but now you have to make a choice.

Do you shut down the line, unmount the sensors, and ship them away for a week? Or do you pay to have a technician bring their equipment to you?

This is the classic debate of On-Site vs Lab Calibration.

ADYAA offers both services because we know that no two facilities are the same. However, making the wrong choice can either cost you unnecessary downtime or compromise your accuracy results. As calibration specialists, we are here to help you decide which route is right for your specific assets.

Laboratory calibration is the traditional method where you remove your instrument—be it a pressure gauge, temperature transmitter, or flow meter—and ship it to a controlled environment like ADYAA’s certified lab.

Best For: Primary reference standards, highly critical quality control instruments, and lightweight portable devices.

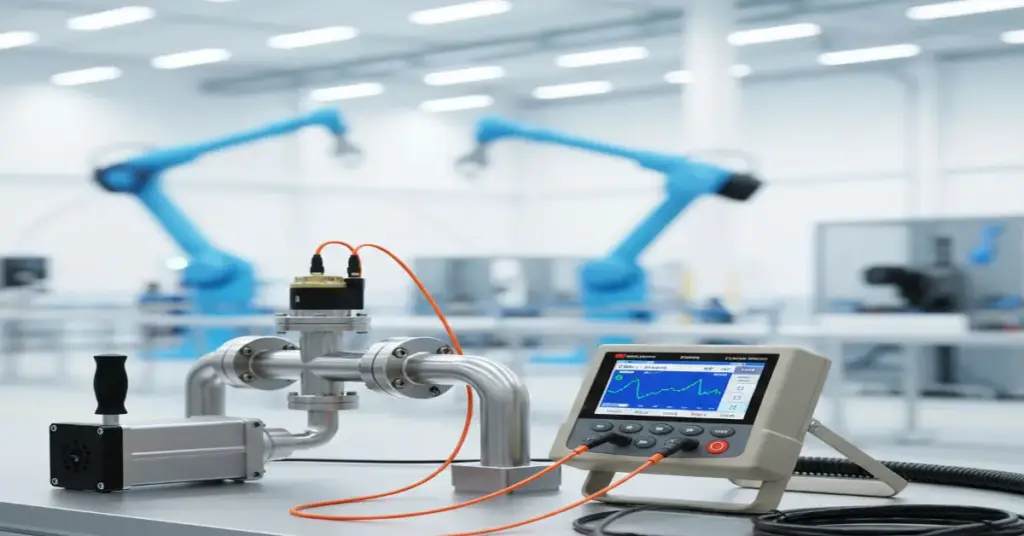

On-site calibration brings the technician and their portable reference standards directly to your plant.

Best For: Heavy integrated machinery, continuous process lines (Oil & Gas, Food & Beverage), and facilities with hundreds of gauges to check at once.

To make the decision clearer, let’s look at how On-Site vs Lab Calibration compares across three critical factors:

In a lab, we can achieve the lowest possible measurement uncertainties (the “margin of error”). On-site, while still fully compliant and traceable to national standards, the environment is less stable. If you need to calibrate a master gauge used to check other gauges, send it to the lab. If you are calibrating a standard process switch, on-site is more than accurate enough.

If removing a flow meter requires draining a pipe and stopping production for a week, the cost of lost business dwarfs the cost of the calibration service. In this scenario, on-site is the only logical choice.

Calibration doesn’t exist in a vacuum. It is the health check that protects your entire ecosystem.

So, when weighing up On-Site vs Lab Calibration, ask yourself three questions:

If you answered “No” to the last question, you need ADYAA’s on-site team.

ADYAA provides NATA-traceable reports regardless of where the work is done. Whether you need the surgical precision of our lab or the rapid response of our field team, we ensure your sensors tell the truth.

Unsure which service fits your schedule?

Compare Our Calibration Services & Get a Quote

Chat with a specialist today to plan your next shutdown.