Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems

Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems In the world of industrial automation and pneumatic power, water is the enemy. It is invisible in its vapor form, but once it condenses into liquid, it becomes a destructive force capable of rusting pipes, ruining sensitive tools, and contaminating end products. Many facilities focus heavily on pressure and flow, often treating moisture monitoring as an afterthought. However, seasoned engineers know that Dew Point Sensors Are Critical in Industrial Air and Gas Systems for maintaining operational integrity and efficiency. ADYAA specializes in the instrumentation that keeps your processes safe. In this deep dive, we explore the science of dew point and why ignoring it is a risk you cannot afford to take. What Is Dew Point and Why Does It Matter? “Dew Point” is the temperature at which air becomes saturated with water vapor. If the air cools below this temperature, the airborne vapor turns into liquid water (condensation). In industrial contexts, we specifically talk about Pressure Dew Point (PDP). Because compressing air concentrates the water vapor, the dew point rises significantly under pressure. Air that seems “dry” at ambient pressure will immediately drop gallons of water once compressed if not properly treated. Understanding this thermodynamic reality is the first step in realizing why Dew Point Sensors Are Critical in Industrial Air and Gas Systems. Without them, you are flying blind regarding the moisture content in your lines. The 4 Major Risks of Unmonitored Moisture If you are not actively monitoring dew point, you are likely experiencing one of these four expensive problems: 1. Corrosion and Equipment Failure Water in pneumatic lines washes away the lubricants needed for cylinders and valves. Over time, this causes: Rust and Scale: This debris travels through the pipes, clogging orifices and damaging expensive actuators. Frozen Lines: In outdoor installations or cold climates, condensed water freezes, blocking airflow and potentially bursting pipes. 2. Product Contamination (Food & Pharma) In regulated industries, air often touches the product. Imagine a pharmaceutical powder clumping because the conveying air was moist, or bacteria growing in a food package because the “clean” air contained water droplets. In these high-stakes environments, Dew Point Sensors Are Critical in Industrial Air and Gas Systems to ensure compliance with strict hygiene standards like ISO 8573-1. 3. Compromised Analytical Instruments Many industrial analyzers and precision instruments require “Zero Air” or ultra-dry gas to function. Moisture can drift sensor readings or permanently damage the sensitive optics and detection elements inside these devices. 4. Energy Waste in Dryers Most facilities use Desiccant or Refrigerant dryers to remove moisture. Without a sensor, these dryers often run on a fixed timer—regenerating the desiccant beds every 10 minutes whether they need it or not. By using a dew point sensor to control the dryer (Dew Point Demand Switching), you only regenerate when the sensor detects moisture. This can save thousands of dollars in energy costs annually. Choosing the Right Sensor Technology Not all sensors are created equal. Selecting the right one depends on how dry your air needs to be. Polymer Sensors: Excellent for standard compressed air applications (Refrigerant dryers) where the dew point is around +3°C. They are robust, fast-responding, and cost-effective. Aluminum Oxide / Metal Oxide Sensors: The standard for “critical dry” air (Desiccant dryers) where dew points can reach -40°C or even -100°C. These are highly sensitive and essential for semiconductor or medical gas applications. Installation Best Practices To ensure your data is accurate, proper installation is key. Install at the Point of Use: While checking the compressor room is important, measuring at the end of the line (near the critical machine) ensures that no moisture has re-entered the system through leaks. Use a Sampling Cell: Placing a sensor directly in a high-velocity air stream can damage it or cause errors. A sampling cell controls the flow across the sensor for a stable reading. Regular Calibration: Like all precision instruments, dew point sensors drift over time. Regular calibration (as offered by ADYAA) ensures you aren’t relying on false “dry” readings. Conclusion: A Small Sensor for Big Peace of Mind Moisture damage is cumulative. By the time you see water dripping out of a pneumatic tool, the damage to the internal seals is already done. Implementing continuous monitoring is the only proactive solution. It allows you to catch dryer failures instantly, automate energy savings, and guarantee product quality. This is why Dew Point Sensors Are Critical in Industrial Air and Gas Systems—they are the final check that validates your entire air treatment process. ADYAA supplies a range of high-precision dew point transmitters and portable meters designed for the harsh conditions of Australian industry. Stop guessing about your air quality. View ADYAA’s Range of Dew Point Sensors Contact our team to discuss your compressed air requirements. Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems In the world of industrial automation and pneumatic… Read More → Understanding Thermowells and Their Role in Process Instrumentation Understanding Thermowells and Their Role in Process Instrumentation In the vast ecosystem of process control, temperature is often the most… Read More → 5 Signs Your Equipment Needs Calibration Now 5 Signs Your Equipment Needs Calibration Now In a perfect world, you would calibrate your instruments exactly according to the… Read More →

Understanding Thermowells and Their Role in Process Instrumentation

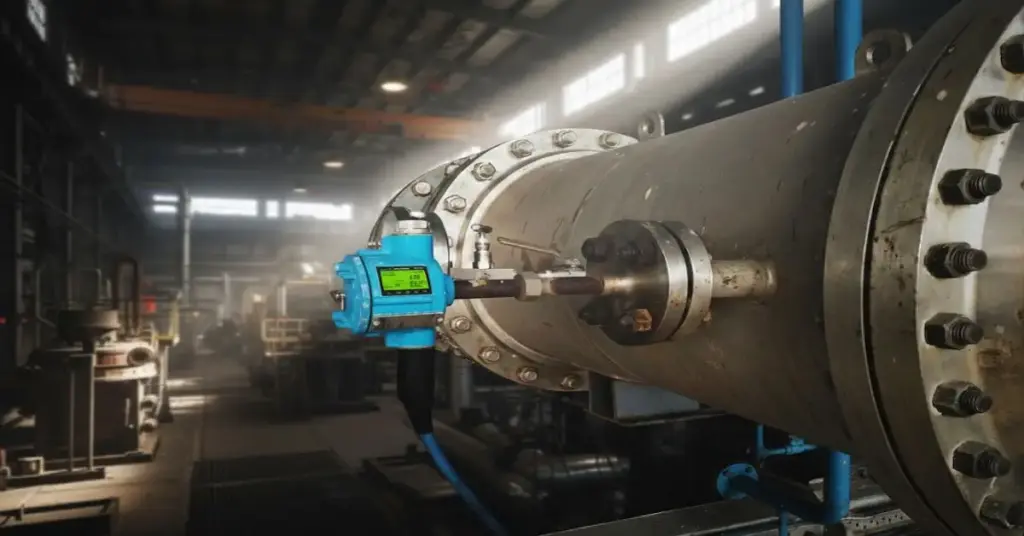

Understanding Thermowells and Their Role in Process Instrumentation In the vast ecosystem of process control, temperature is often the most critical variable. Whether you are refining crude oil, pasteurizing milk, or managing chemical reactions, accurate temperature data is non-negotiable. However, the sensors that measure this temperature—Resistance Temperature Detectors (RTDs) and Thermocouples—are often delicate devices. Shutterstock They contain fine wires and sensitive elements that would be destroyed instantly if exposed directly to high-velocity steam, corrosive acids, or abrasive slurries. Enter the Thermowell. Often overlooked as a simple metal fitting, the thermowell is actually a critical safety barrier. ADYAA, knows that selecting the wrong thermowell doesn’t just mean a broken sensor; it can lead to catastrophic vessel failure. In this guide, we break down everything you need to know about thermowells and their role in process instrumentation. What Is a Thermowell? A Thermowell is a cylindrical pressure-tight fitting that protects temperature sensors from the process media. Think of it as “armor” for your sensor. It is installed directly into the pipe or vessel, and the temperature sensor (the probe) is inserted into the open end of the thermowell. The heat transfers from the process fluid, through the thermowell wall, and into the sensor. The Three Primary Functions Protection: It isolates the fragile sensor from pressure, high velocity, and corrosion. Serviceability: This is arguably its most important role for operations. A thermowell allows you to remove and replace a faulty sensor without shutting down the process or draining the tank. Containment: It acts as a part of the process boundary. If the sensor is removed, the thermowell keeps the liquid or gas inside the pipe. Anatomy of a Thermowell: Stem Profiles Not all thermowells are simple tubes. The shape of the “stem” (the part immersed in the fluid) dictates how the well handles pressure and how fast it responds to temperature changes. 1. Straight Stem The same diameter along the entire immersion length. Pros: Strong and easy to manufacture. Cons: Slower response time due to more metal mass at the tip; susceptible to flow-induced vibration. 2. Stepped Stem The diameter is reduced (stepped down) at the tip where the sensor sits. Pros: Faster response time (less metal at the tip) and good strength. Cons: Slightly lower pressure rating than tapered. Verdict: The most common standard for general industry. 3. Tapered Stem The diameter gradually decreases from the root to the tip. Pros: The strongest design. It offers the best resistance to vibration and high-velocity flow. Cons: More expensive to machine. Verdict: Essential for high-velocity steam lines and heavy-duty petrochemical applications. Connection Types: How It Fits Your Process Threaded: Screws directly into the pipe. Low cost and easy to install, but not recommended for high pressure or flammable/hazardous materials due to the risk of leakage at the threads. Flanged: The thermowell is welded to a flange, which is bolted to a mating flange on the pipe. This is the standard for Oil & Gas and Chemical industries as it provides a secure, high-pressure seal. Socket Weld / Weld-In: Welded directly into the pipe wall. This is a permanent solution used for extremely high pressure (like steam generation) where no leakage path is permitted. The Hidden Danger: Wake Frequency and Vibration This is the most technical and critical part of thermowell selection. When fluid flows past a thermowell, it doesn’t just flow smoothly; it creates vortices (swirls) that shed from alternating sides of the stem. This is known as the Von Karman Vortex Street. These shedding vortices create oscillating forces that make the thermowell vibrate. The Risk: If the frequency of these vibrations matches the Natural Frequency of the thermowell (its resonant “sweet spot”), the thermowell will vibrate violently and snap off inside the pipe. The Result: The sensor is lost, and worse, you now have an open hole in your pipe spewing process fluid. The Solution: Always perform a Wake Frequency Calculation (per ASME PTC 19.3 TW-2016 standards) before installing thermowells in high-velocity lines. This calculation ensures the stem is thick enough and short enough to withstand the flow. Selecting the Right Material Since the thermowell is in direct contact with the media, material selection is vital to prevent corrosion. Stainless Steel (304/316): The industry standard for water, air, and mild chemicals. Monel / Hastelloy: Required for seawater or highly corrosive acids (Hydrochloric/Sulfuric). Inconel / Ceramic: Used for extremely high temperatures (furnaces and kilns) where steel would melt or oxidize. Conclusion: Small Component, Big Impact A thermowell might look like a simple piece of metal, but it is a highly engineered component that bridges the gap between delicate electronics and brutal industrial forces. Ignoring the details—like immersion length, material compatibility, or wake frequency—can lead to poor measurement accuracy or dangerous mechanical failures. ADYAA specializes in understanding that instrumentation isn’t just about reading a number on a screen; it’s about the safety and efficiency of your entire plant. Need help sizing the right thermowell for your application? Contact ADYAA’s Instrumentation Team Let us handle your Wake Frequency Calculations and material selection today. Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems In the world of industrial automation and pneumatic… Read More → Understanding Thermowells and Their Role in Process Instrumentation Understanding Thermowells and Their Role in Process Instrumentation In the vast ecosystem of process control, temperature is often the most… Read More → 5 Signs Your Equipment Needs Calibration Now 5 Signs Your Equipment Needs Calibration Now In a perfect world, you would calibrate your instruments exactly according to the… Read More →

5 Signs Your Equipment Needs Calibration Now

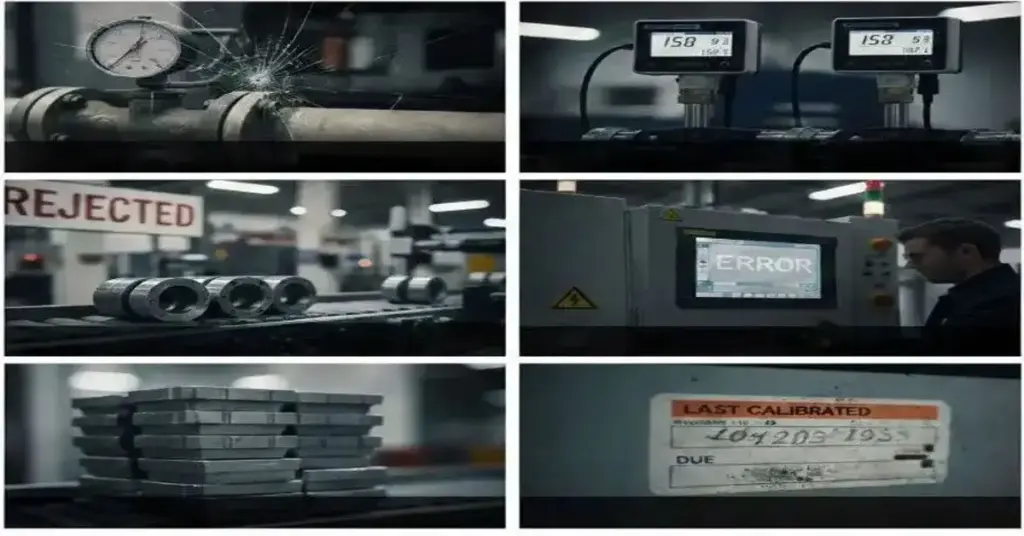

5 Signs Your Equipment Needs Calibration Now In a perfect world, you would calibrate your instruments exactly according to the manufacturer’s schedule—every 6 or 12 months, like clockwork. But in the real world of busy production schedules and tight budgets, maintenance sometimes slips. The problem is, your sensors don’t wait for a schedule to start failing. Drift happens. Wear and tear happen. Accidents happen. Relying on an outdated sticker to tell you if your equipment needs calibration is a risky strategy. Often, your machinery will tell you it’s struggling long before the due date arrives—you just have to know what to listen for. We help industries across Australia stay accurate. Here are the 5 red flags that indicate your equipment needs calibration immediately. 1. Your Product Quality Is Inconsistent The first victim of poor calibration is usually the product itself. The Symptom: You are running the same “recipe” or settings as always, but the results are changing. Maybe the chemical mix is slightly off, the coating thickness varies (a critical issue for our Elcometer users), or the fill levels in bottles are erratic. The Cause: If a flow meter or temperature sensor drifts, the machine thinks it is doing the right thing, but the reality doesn’t match the data. The Fix: If your output quality wavers, don’t blame the raw materials first. Check if your equipment needs calibration. 2. Readings Don’t Match “Common Sense” Experienced operators know their machines by heart. They know that when Pump A is running at 50Hz, the pressure usually sits at 5 Bar. The Symptom: A gauge shows zero pressure when a line is clearly pressurized, or a temperature sensor reads ambient room temp as 40°C. The Cause: Internal electronic components can fail, or diaphragms can become stiff. The Reality: Trust your operators. If they say “that gauge looks wrong,” it is a clear sign the equipment needs calibration or replacement. 3. Physical Damage or “Shock” Events Industrial environments are tough. Tools get dropped, forklifts bump into panels, and steam lines experience “water hammer.” The Symptom: A visible dent in a transmitter housing, a cracked gauge face, or a sensor that has been exposed to a sudden over-pressure spike. The Rule: Any instrument that suffers a significant physical shock is compromised. Even if it still “works,” the internal mechanism may be bent or shifted. The Fix: Don’t wait for the annual check. A shocked sensor is an unreliable sensor. 4. Energy Bills Are Spiking As we explored in our post on Industrial Automation Sensors, efficiency relies on accurate data. The Symptom: Your power consumption is creeping up, but production volume hasn’t increased. The Cause: If a temperature sensor reads lower than the actual temperature, a boiler or heater will burn extra fuel trying to reach a setpoint it has already exceeded. The Reality: In this case, the cost of the wasted energy is often higher than the cost of the service. This phantom cost is a major indicator that your equipment needs calibration. 5. You Have an Audit or Certification Coming Up This is the most common trigger, but often it’s left too late. The Symptom: An ISO 9001, API, or safety audit is scheduled for next month, and you realize your certificates expired three weeks ago. The Risk: An auditor finding an expired label on a critical control point is an immediate non-conformance. The Fix: Proactive planning. If an audit is looming, review every critical asset. If the date is close, assume the equipment needs calibration now to avoid the scramble. Don’t Guess—Verify. Ignoring these signs leads to scrap, safety hazards, and downtime. Whether you need a quick verification of a handheld device or a full loop check of a critical safety system, ADYAA has the solution. We offer both On-Site and Lab Calibration to suit your urgency. If you spot any of these 5 signs, do not wait for the breakdown. Think your sensors are drifting? Schedule a Calibration Check with ADYAA Call our support team for emergency service. Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems In the world of industrial automation and pneumatic… Read More → Understanding Thermowells and Their Role in Process Instrumentation Understanding Thermowells and Their Role in Process Instrumentation In the vast ecosystem of process control, temperature is often the most… Read More → 5 Signs Your Equipment Needs Calibration Now 5 Signs Your Equipment Needs Calibration Now In a perfect world, you would calibrate your instruments exactly according to the… Read More →

Coating Thickness Inspection for Improved Process Reliability

Coating Thickness Inspection for Improved Process Reliability In industrial manufacturing, a layer of paint or coating is rarely just for decoration. It is a functional shield designed to protect expensive assets from corrosion, abrasion, and extreme temperatures. However, applying this shield is a delicate balancing act. Apply too little, and the protection fails prematurely. Apply too much, and you waste expensive material or cause issues like cracking and prolonged curing times. This is where Coating Thickness Inspection becomes the linchpin of process reliability. ADYAA, understands that reliable measurement is the difference between a product that lasts for decades and one that fails in months. In this guide, we explore the methods, standards, and strategic value of rigorous thickness testing. Why Coating Thickness Matters The thickness of a coating—often referred to as Dry Film Thickness (DFT)—is the most critical parameter in determining the lifespan of a protective system. Corrosion Prevention: Most industrial specifications (like ISO 12944) mandate a specific minimum thickness to ensure an adequate barrier against moisture and oxygen. Mechanical Fit: In precision engineering, an overly thick coating can interfere with the assembly of parts, causing production delays. Cost Control: “Over-coating” by just 10% across a year of production can cost a factory thousands of dollars in wasted paint. By implementing a strict Coating Thickness Inspection regime, you ensure that every part meets the “Goldilocks” standard—not too thick, not too thin, but just right. Methods of Inspection: How It Works Modern technology allows us to measure thickness without damaging the part. The method you choose depends heavily on the substrate (the material underneath the paint). 1. Magnetic Induction (Ferrous Substrates) This is the standard method for measuring non-magnetic coatings (paint, plastic, galvanizing) over magnetic substrates like steel or iron. How it works: The probe generates a magnetic field. The thickness of the coating changes the magnetic flux between the probe and the steel. The gauge converts this change into a thickness reading. 2. Eddy Current (Non-Ferrous Substrates) Used for measuring non-conductive coatings (anodizing, paint) on non-magnetic metals like aluminum, copper, or stainless steel. How it works: The probe creates high-frequency magnetic fields that induce eddy currents in the metal. The coating thickness affects the magnitude of these currents. 3. Ultrasonic Testing (Non-Metal Substrates) For measuring coatings on wood, concrete, or plastic, magnetic methods won’t work. Coating Thickness Inspection in these applications relies on ultrasonic pulses that reflect off the interface between the coating and the substrate. The Role of Calibration in Inspection You cannot trust your data if you cannot trust your gauge. Before every shift or critical batch, your Coating Thickness Inspection tools must be verified. This usually involves: Zeroing: Measuring on the uncoated, smooth substrate. Foil Calibration: Measuring a certified plastic shim of known thickness (e.g., 50 microns) placed over the substrate to ensure the gauge reads correctly. ADYAA supplies industry-leading gauges (such as Elcometer) and offer calibration services to ensure your NDT equipment remains traceable to national standards. How Inspection Improves Process Reliability Moving from “visual checking” to data-driven Coating Thickness Inspection transforms your operations in three ways: 1. Predictive Quality Control By integrating digital gauges that store data, you can track trends. If the average thickness is slowly creeping up over a week, you know a spray nozzle might be wearing out or a robot needs reprogramming before you start producing defective parts. 2. Compliance and Liability Protection In sectors like marine, aerospace, and oil & gas, proof of quality is mandatory. A digital inspection log provides a permanent record that the coating was applied according to spec. This is your insurance policy against warranty claims later. 3. Reducing Rework Catching a low-thickness area immediately after the curing oven allows for a quick touch-up. Catching it after the product has been shipped to the customer results in expensive field repairs and reputational damage. Reliable Coating Thickness Inspection keeps the problem inside the factory walls where it can be managed. Conclusion: Precision is Protection A coating is only as good as its application. Without accurate measurement, you are essentially guessing. Investing in high-quality inspection equipment and training your team on proper probe placement and calibration techniques is one of the highest-ROI activities a paint shop can undertake. It reduces waste, ensures compliance, and guarantees that your product can withstand the environment it was built for. Looking for reliable inspection tools? At ADYAA, we stock a wide range of NDT solutions, including the world-renowned Elcometer series. Explore Our Coating Thickness Gauges Contact our experts for advice on measuring complex substrates. Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems In the world of industrial automation and pneumatic… Read More → Understanding Thermowells and Their Role in Process Instrumentation Understanding Thermowells and Their Role in Process Instrumentation In the vast ecosystem of process control, temperature is often the most… Read More → 5 Signs Your Equipment Needs Calibration Now 5 Signs Your Equipment Needs Calibration Now In a perfect world, you would calibrate your instruments exactly according to the… Read More →

On-Site vs Lab Calibration: Which is Best for Your Facility?

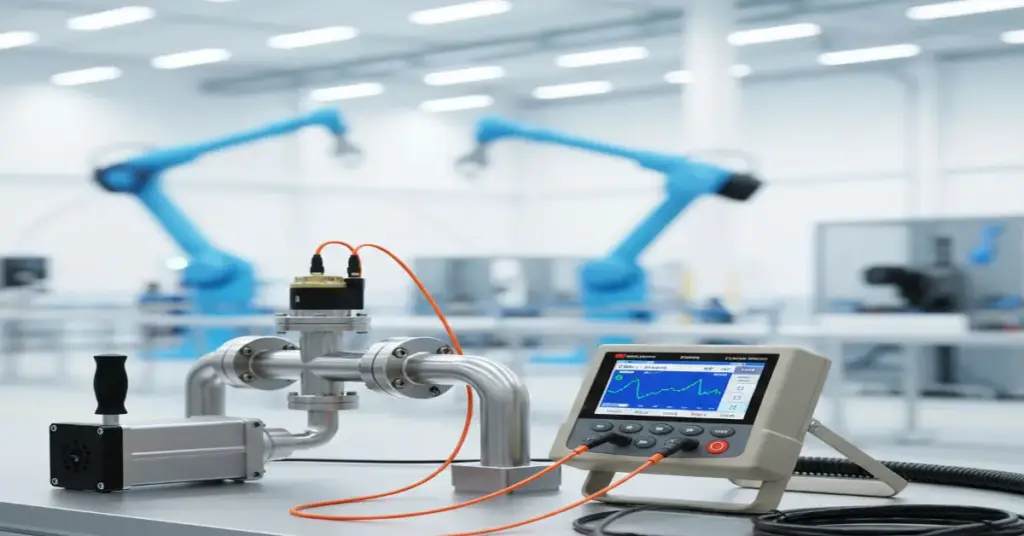

On-Site vs Lab Calibration: Which is Best for Your Facility? Every maintenance manager faces the same dilemma eventually. You have a critical audit coming up, or perhaps your process data looks slightly “off.” You know your instruments need attention, but now you have to make a choice. Do you shut down the line, unmount the sensors, and ship them away for a week? Or do you pay to have a technician bring their equipment to you? This is the classic debate of On-Site vs Lab Calibration. ADYAA offers both services because we know that no two facilities are the same. However, making the wrong choice can either cost you unnecessary downtime or compromise your accuracy results. As calibration specialists, we are here to help you decide which route is right for your specific assets. The Gold Standard: What is Lab Calibration? Laboratory calibration is the traditional method where you remove your instrument—be it a pressure gauge, temperature transmitter, or flow meter—and ship it to a controlled environment like ADYAA’s certified lab. Why Choose the Lab? Ultimate Precision: Our lab is environmentally controlled. Temperature, humidity, and vibration are strictly managed. This eliminates external variables that could skew the reading of highly sensitive master equipment. Full Range Testing: Some equipment requires massive reference standards (like large flow rigs or high-temperature furnaces) that simply cannot be put in a van. Deep Diagnostics: If a unit fails, we have the tools on the bench to dismantle, clean, and repair it immediately—something that is hard to do on a factory floor. Best For: Primary reference standards, highly critical quality control instruments, and lightweight portable devices. The Agile Alternative: What is On-Site Calibration? On-site calibration brings the technician and their portable reference standards directly to your plant. Why Choose On-Site? Zero Shipping Risks: Delicate instruments can be damaged during shipping. On-site eliminates this risk entirely. Minimal Downtime: This is the biggest advantage. A sensor might be out of service for 30 minutes instead of 5 days. Contextual Testing: We test the instrument in its actual operating environment. Sometimes, “drift” isn’t caused by the sensor, but by the installation (e.g., a loose cable or vibration). Our technicians can spot these environmental issues immediately. Best For: Heavy integrated machinery, continuous process lines (Oil & Gas, Food & Beverage), and facilities with hundreds of gauges to check at once. The Showdown: On-Site vs Lab Calibration To make the decision clearer, let’s look at how On-Site vs Lab Calibration compares across three critical factors: 1. Accuracy and Uncertainties In a lab, we can achieve the lowest possible measurement uncertainties (the “margin of error”). On-site, while still fully compliant and traceable to national standards, the environment is less stable. If you need to calibrate a master gauge used to check other gauges, send it to the lab. If you are calibrating a standard process switch, on-site is more than accurate enough. 2. Cost Implications Lab: You pay for shipping and the calibration fee. On-Site: You pay for the technician’s travel and time. The Verdict: If you only have one or two items, the lab is cheaper. If you have 50 pressure transmitters, On-Site vs Lab Calibration swings heavily in favor of on-site, as the bulk volume justifies the travel cost. 3. Production Impact If removing a flow meter requires draining a pipe and stopping production for a week, the cost of lost business dwarfs the cost of the calibration service. In this scenario, on-site is the only logical choice. Connecting the Dots: Calibration and System Health Calibration doesn’t exist in a vacuum. It is the health check that protects your entire ecosystem. Protecting Seals: As we discussed in our guide on Industrial Sealing, over-pressurization is a leading cause of gasket blowouts. Accurate pressure sensors ensure your system stays within safe limits, protecting your RTJ Gaskets and flanges. Validating Automation: Your Industrial Automation Sensors Are Only as Good as Their Calibration. A vision sensor or laser distance meter that drifts by 1mm can result in thousands of rejected products. Regular calibration closes the loop on quality control. Making the Final Call So, when weighing up On-Site vs Lab Calibration, ask yourself three questions: Can this item be easily removed? Is this the most critical reference standard in my plant? Can I afford for this device to be gone for 3-5 days? If you answered “No” to the last question, you need ADYAA’s on-site team. ADYAA provides NATA-traceable reports regardless of where the work is done. Whether you need the surgical precision of our lab or the rapid response of our field team, we ensure your sensors tell the truth. Unsure which service fits your schedule? Compare Our Calibration Services & Get a Quote Chat with a specialist today to plan your next shutdown. Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems Why Dew Point Sensors Are Critical in Industrial Air and Gas Systems In the world of industrial automation and pneumatic… Read More → Understanding Thermowells and Their Role in Process Instrumentation Understanding Thermowells and Their Role in Process Instrumentation In the vast ecosystem of process control, temperature is often the most… Read More → 5 Signs Your Equipment Needs Calibration Now 5 Signs Your Equipment Needs Calibration Now In a perfect world, you would calibrate your instruments exactly according to the… Read More →

How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing

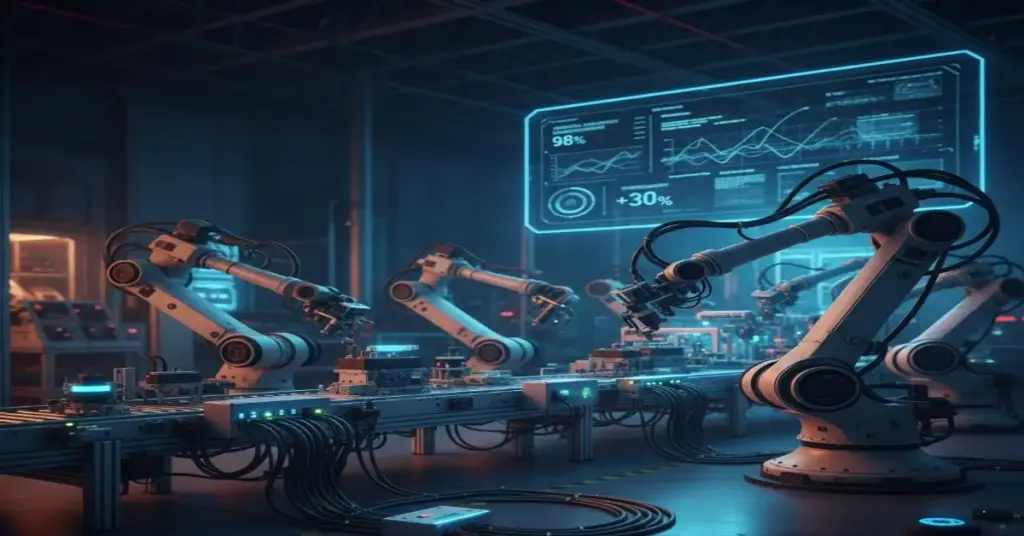

How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important than ever. Industrial automation sensors play a pivotal role in helping manufacturers achieve these objectives. ADYAA offers high-quality industrial sensors designed by Prominent Brands including Baumer to enhance productivity, reduce downtime, and ensure consistent product quality. What Are Industrial Automation Sensors? Industrial automation sensors are devices that detect changes in physical parameters and communicate this information to control systems. By delivering real-time data, these sensors allow machines to operate optimally and adapt quickly to precise conditions. Key Types of Industrial Sensors Object and Position Sensors: Identify the presence and position of items. Range and Distance Sensors: Measure distances with high precision using ultrasonic, laser, or radar technologies. Vision and Imaging Systems: Inspect products to detect defects and support automated quality checks. Encoders: Track motion, speed, and position for robotic and mechanical systems. Inclination and Acceleration Sensors: Monitor tilt and movement to maintain stability and safety. Force and Load Sensors: Measure pressure, weight, and force to improve production accuracy. ADYAA’s sensors are suitable for diverse industries including automotive, electronics, food processing, and pharmaceuticals. How Sensors Empower Automation Automation thrives on accurate, real-time information. Industrial sensors offer multiple advantages: Continuous Monitoring: Real-time tracking of equipment conditions for immediate response. Higher Accuracy: Precise sensors reduce human errors, ensuring consistent results. Predictive Maintenance: Detect early signs of wear, vibration, or heat to avoid unexpected breakdowns. Enhanced Safety: Identify unsafe conditions to protect workers and equipment. Boosting Overall Manufacturing Efficiency Beyond automation, sensors contribute to smoother and more efficient operations: Energy Savings: Machines operate only when necessary, minimizing power consumption. Reduced Waste: Accurate measurements limit raw material waste. Accelerated Production: Real-time adjustments ensure uninterrupted workflows. Data-Driven Insights: Collected sensor data helps identify inefficiencies and optimize processes. Practical Applications in Manufacturing Automotive: Enable precise robotic assembly and quality inspection. Logistics and Material Handling: Track items and automate sorting processes. Heavy Machinery: Measure force, load, and movement to ensure safe operations. Conclusion Industrial automation sensors provide the essential real-time insights manufacturers need for smarter, faster, and safer production. Using ADYAA’s advanced sensors, businesses can reduce waste, improve quality, save energy, and minimize downtime. Investing in cutting-edge sensors is a vital step toward creating efficient, reliable, and high-performing manufacturing processes. Next Steps: Explore ADYAA’s Industrial Sensors Collection Contact ADYAA’s technical team for expert advice How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing How Industrial Automation Sensors Improve Automation & Efficiency in Manufacturing In modern manufacturing, efficiency, accuracy, and reliability are more important… Read More → How Vision & Imaging Sensors Transform Automated Inspection Systems How Vision & Imaging Sensors Transform Automated Inspection Systems Maintaining product quality while keeping up with high-speed production is crucial…. Read More → IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability IoT and Automation in Industrial Operations: Boost Efficiency, Safety, and Reliability Discover how IoT and automation revolutionize industrial operations. Improve… Read More →