In a perfect world, you would calibrate your instruments exactly according to the manufacturer’s schedule—every 6 or 12 months, like clockwork. But in the real world of busy production schedules and tight budgets, maintenance sometimes slips.

The problem is, your sensors don’t wait for a schedule to start failing.

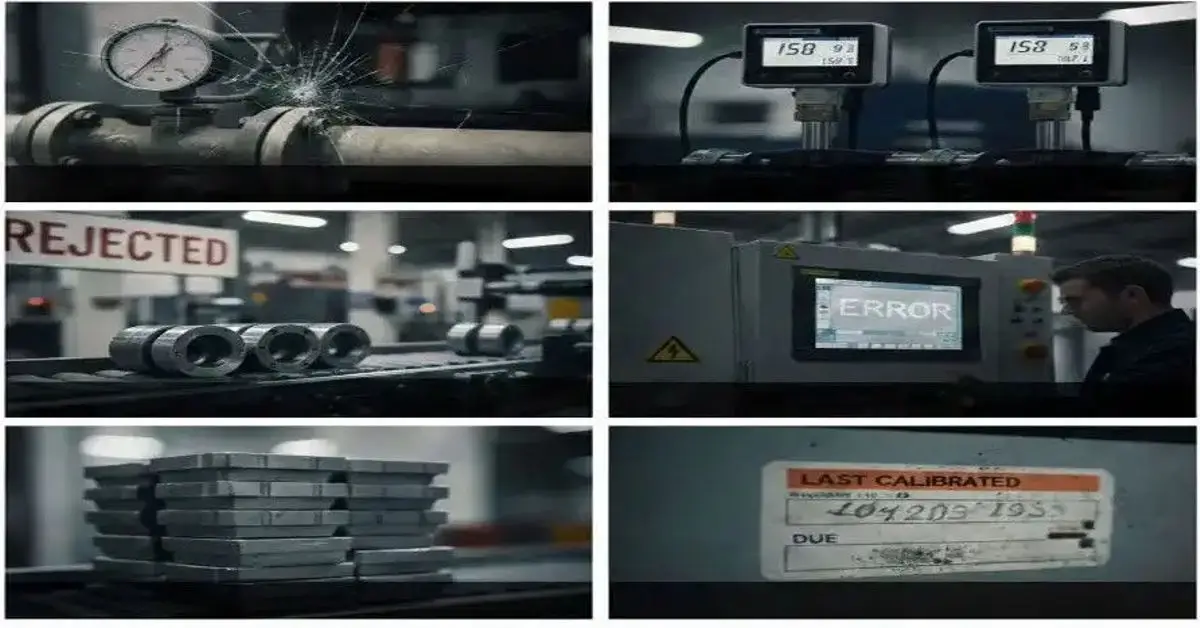

Drift happens. Wear and tear happen. Accidents happen. Relying on an outdated sticker to tell you if your equipment needs calibration is a risky strategy. Often, your machinery will tell you it’s struggling long before the due date arrives—you just have to know what to listen for.

We help industries across Australia stay accurate. Here are the 5 red flags that indicate your equipment needs calibration immediately.

1. Your Product Quality Is Inconsistent

The first victim of poor calibration is usually the product itself.

- The Symptom: You are running the same “recipe” or settings as always, but the results are changing. Maybe the chemical mix is slightly off, the coating thickness varies (a critical issue for our Elcometer users), or the fill levels in bottles are erratic.

- The Cause: If a flow meter or temperature sensor drifts, the machine thinks it is doing the right thing, but the reality doesn’t match the data.

- The Fix: If your output quality wavers, don’t blame the raw materials first. Check if your equipment needs calibration.

2. Readings Don’t Match “Common Sense”

Experienced operators know their machines by heart. They know that when Pump A is running at 50Hz, the pressure usually sits at 5 Bar.

- The Symptom: A gauge shows zero pressure when a line is clearly pressurized, or a temperature sensor reads ambient room temp as 40°C.

- The Cause: Internal electronic components can fail, or diaphragms can become stiff.

- The Reality: Trust your operators. If they say “that gauge looks wrong,” it is a clear sign the equipment needs calibration or replacement.

3. Physical Damage or “Shock” Events

Industrial environments are tough. Tools get dropped, forklifts bump into panels, and steam lines experience “water hammer.”

- The Symptom: A visible dent in a transmitter housing, a cracked gauge face, or a sensor that has been exposed to a sudden over-pressure spike.

- The Rule: Any instrument that suffers a significant physical shock is compromised. Even if it still “works,” the internal mechanism may be bent or shifted.

- The Fix: Don’t wait for the annual check. A shocked sensor is an unreliable sensor.

4. Energy Bills Are Spiking

As we explored in our post on Industrial Automation Sensors, efficiency relies on accurate data.

- The Symptom: Your power consumption is creeping up, but production volume hasn’t increased.

- The Cause: If a temperature sensor reads lower than the actual temperature, a boiler or heater will burn extra fuel trying to reach a setpoint it has already exceeded.

- The Reality: In this case, the cost of the wasted energy is often higher than the cost of the service. This phantom cost is a major indicator that your equipment needs calibration.

5. You Have an Audit or Certification Coming Up

This is the most common trigger, but often it’s left too late.

- The Symptom: An ISO 9001, API, or safety audit is scheduled for next month, and you realize your certificates expired three weeks ago.

- The Risk: An auditor finding an expired label on a critical control point is an immediate non-conformance.

- The Fix: Proactive planning. If an audit is looming, review every critical asset. If the date is close, assume the equipment needs calibration now to avoid the scramble.

Don’t Guess—Verify.

Ignoring these signs leads to scrap, safety hazards, and downtime. Whether you need a quick verification of a handheld device or a full loop check of a critical safety system, ADYAA has the solution.

We offer both On-Site and Lab Calibration to suit your urgency. If you spot any of these 5 signs, do not wait for the breakdown.

Think your sensors are drifting?

Schedule a Calibration Check with ADYAA

Call our support team for emergency service.