When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

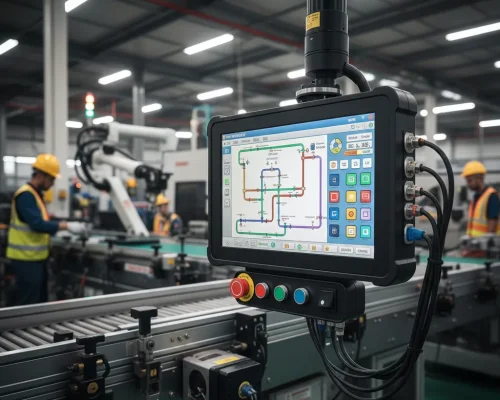

Experience next-generation control with our revolutionary CP Series industrial HMI (Human Machine Interface) state-of-the-art, rugged touchscreens delivering intuitive, real-time monitoring and seamless integration for future-proof automation.

Get application-specific solutions from our technical specialists.

Enjoy responsive service backed by global ABB technology.

Simplify meeting and documenting environmental standards.

Unleash next-level efficiency with our IP66-rated industrial HMI panels—boasting high-resolution touchscreens, ARM Cortex-A8 performance, and built-in web-based runtimes for seamless, real-time process visualization and control.

4.3″ HMI touchscreen (480×272 px, 64K colors) for crisp, compact displays.

Embedded PB610 web HMI for seamless PLC integration and remote access.

IP66-rated front panel (18–32 V DC, 0–50 °C) for rugged industrial use.

60 MB onboard memory with Ethernet, RS-232/485 & USB ports for flexible connectivity.

4.3″ TFT HMI (480×272, 64K colors) – vivid, compact operator display.

PB610-eCo + AC500 V3 web runtime – versatile, secure HMI dashboards.

300 MHz Cortex-A8, 256 MB RAM, 2 GB flash & 60 MB project storage.

IP66 front, 18–32 V DC, 0–50 °C, Ethernet/RS-232/485 & USB for rugged connectivity.

Industrial 7″ HMI touchscreen (800×480 px, 64K colors) for sharp, intuitive operator visuals.

Rugged IP66-rated front panel (18–32 V DC, 0–50 °C) for dependable performance in dust- and water-prone environments.

60 MB onboard memory tuned for PB610-eCo runtime, accelerating data logging and dynamic screen rendering.

Slim 187×147×34 mm, 0.5 kg profile with Ethernet & USB ports for seamless automation integration.

7″ resistive TFT touchscreen (800×480, 64K colors) for crisp, intuitive HMI visuals.

PB610 web-based HMI support enables seamless PLC integration and remote monitoring.

IP66-rated front panel protects against dust and water, operating from 0 °C to 50 °C.

Slim 187×147×34 mm, 0.5 kg enclosure with Ethernet and USB ports for versatile connectivity.

10.1″ HMI touchscreen (1024×600, 64K colors) for crisp operator displays.

Integrated Chromium Browser for PB610 & AC500 V3 web HMI.

1 GHz ARM Cortex-A8 CPU with 512 MB RAM and 4 GB flash for smooth operation.

IP66-rated front panel (0 °C–50 °C) plus Ethernet, USB & serial ports for rugged connectivity.

10.1″ resistive HMI touchscreen (1024×600, 64K colors) with Chromium Browser.

IP66-rated front panel (18–32 V DC, 0–50 °C) for harsh industrial conditions.

60 MB internal memory for PB610-eCo, enabling rapid data logging.

282×197×35 mm, 1 kg chassis with Ethernet & USB ports for easy integration.

Vibrant 7″ HMI touchscreen with 800×480 resolution and 64K colors for razor-sharp visuals.

Integrated Chromium Browser for secure, web-based HMI and remote access.

ARM Cortex-A8 core with 512 MB RAM and 4 GB flash for unwavering automation performance.

IP66-rated front panel built to withstand dust, water, and −10 °C to +60 °C extremes.

High-resolution TFT display (800×600 pixels) with 64K colors for clear, responsive control.

Integrated Chromium Browser supports advanced web visualization and PB610 applications.

IP66-rated front panel and wide temperature range (−20°C to +60°C) for reliable field use.

Dual Ethernet ports and USB interfaces for seamless integration with automation systems.

1024×768 resolution with 64K-color support for ultra-clear process visualization.

Built-In Chromium Browser – Secure, web-based HMI access and full PB610 application compatibility.

Dust- and water-resistant design with a −20 °C to +60 °C operating range for harsh industrial environments.

Flexible automation networking and peripheral integration for seamless system expansion.

4.3″–15″, up to 1024×768 px, 64K colors for clear operator displays.

PB610 runtimes, Chromium Browser, AC500 V3 for secure remote access.

ARM Cortex-A8 (300 MHz–1 GHz), 256–512 MB RAM, 60 MB–60,000 kB memory.

IP66 front, 18–32 V DC, –10 °C operation for harsh environments.

Ethernet, USB, RS-232/485, serial ports for PLC/SCADA integration.

Slim 34–40 mm panel-mount, CP604–CP6415 scalable models.

CP604 / CP604-B – 4.3″ compact HMI for small machines, packaging, and conveyors.

CP607 / CP607-B – 7″ mid-range HMI for water, HVAC, and mid-sized machinery.

CP610 / CP610-B – 10.1″ advanced HMI for production lines, robotics, and web dashboards.

CP6407 – Rugged HMI for harsh environments, mining, steel, and heavy equipment.

CP6410 – 10.4″ scalable HMI for energy systems, solar, wind, and SCADA integration.

CP6415 – 15″ large-format HMI for control rooms, power plants, and process industries.

Stay ahead with technology built for efficiency and reliability.

When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

Flange Sealing Solutions for High-Pressure Pipes: Zero Leakage Strategies In...

How to Select Pressure Relief Valves for Industrial Plants If...

How Rupture Discs Protect Pressure Systems from Catastrophic Failure In...

Elevate every operator into a strategist with ADYAA’s ABB HMIs.

Visit ADYAA ENGINEERING

Unit 3, 5 Murphy Street

O’Connor, Perth WA 6163

Australia

Contact: