A Safety Relief Valve (SRV) is a vital protective component in industrial systems, designed to safeguard equipment, processes, and personnel from dangerous overpressure. Its function is to automatically discharge excess pressure from vessels, pipelines, or systems once a preset pressure level is exceeded, and then close again once normal conditions return.

The main role of an SRV is to avoid serious failures by venting surplus pressure. Overpressure can result from various causes, including process disturbances, thermal expansion, mechanical malfunction, or human error. In such cases, the SRV serves as the final layer of protection.

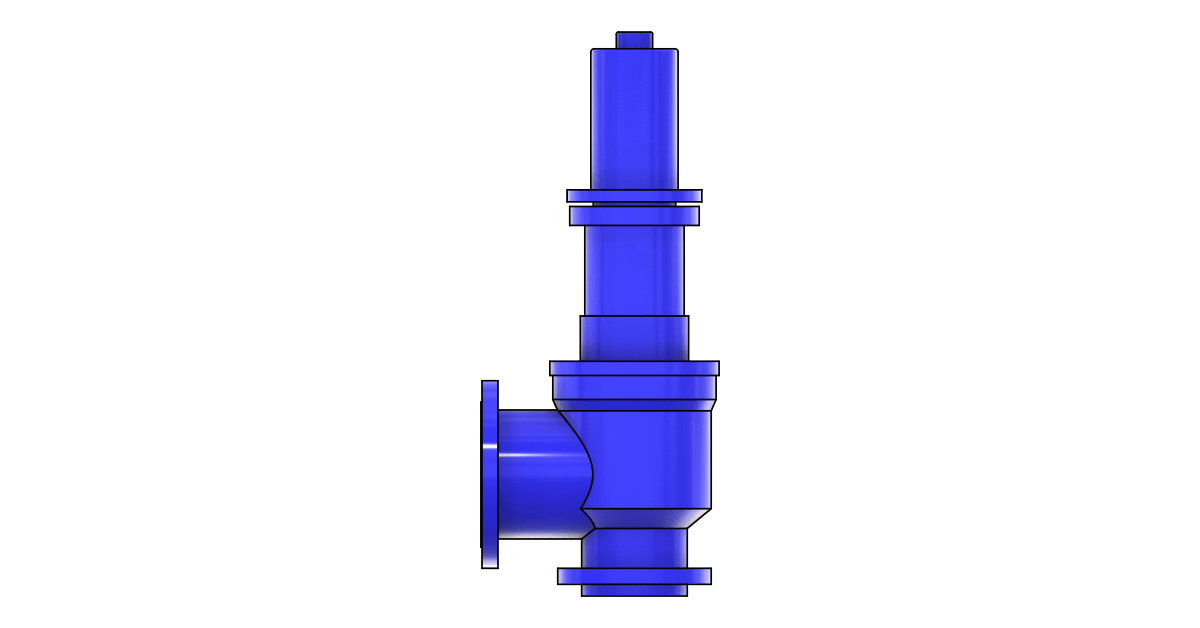

Most SRVs work using a spring-loaded or pilot-operated setup. Under typical conditions, the spring keeps the valve shut. If the system pressure rises above the set value, the force from the fluid overcomes the spring’s tension, lifting the valve disc to release the extra pressure. Once the pressure falls below the set point, the spring pushes the disc back into position, closing the valve and stopping the flow.

Safety Relief Valves must comply with recognized international standards to ensure performance and safety. Commonly followed standards include:

SRVs are commonly found in sectors where overpressure could cause significant hazards, such as:

Without SRVs, overpressure incidents could lead to accidents, major equipment damage, operational downtime, and even loss of life. Selecting, installing, and maintaining the correct SRV is critical for safe and dependable operations.

At Adyaa Engineering, we provide and service certified Safety Relief Valves that conform to international requirements and suit specific applications. Our specialists handle sizing, selection, and testing to ensure top-level safety and reliability.