When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

Read MoreSealing is vital for preventing leaks and ensuring safety in industries handling fluids or gases. ADYAA delivers high-quality, reliable sealing solutions to protect your operations from costly downtime and environmental hazards.

Decades of industry expertise ensure you get the right solution for any application.

We specialize in designing and creating non-standard seals tailored to your unique needs.

We use state-of-the-art techniques to produce superior quality and durable products.

Your complete satisfaction is our priority, and we provide exceptional service to match.

Product Range

High-pressure metal gaskets for oil & gas and refinery flanges. Made as per ASME B16.20/API with oval or octagonal profiles for secure metal-to-metal sealing.

Self-energizing gaskets for offshore, drilling, and API 6A systems. Seal strength increases with pressure, ensuring stability under vibration and temperature swings.

Engineered for 10,000–20,000 PSI flanges in wellheads and HPHT systems. Pressure-energized design prevents blowouts and ensures maximum sealing integrity.

Compact-flange gaskets for subsea and high-pressure systems. Require low bolt load while delivering a strong metal seal in sour-gas and high-temperature service.

Precision 23° metal seals for steam lines, heat exchangers, and high-pressure piping. Maintain leak-tight performance under thermal and pressure variations.

Large lens rings: Ideal for heavy-duty pipelines and large heat exchangers, ensuring uniform sealing at big diameters.

Flexible, corrosion-resistant bellows for chemical plants, dosing pumps, and vacuum systems. Protect internal parts from aggressive media and pressure changes.

PTFE/Xylan coated gaskets for corrosive and sour-gas services. Reduce friction and bolt torque while preventing galling and corrosion.

Precision-machined sealing rings for ball and gate valves. Offer bubble-tight sealing, wear resistance, and long service life in demanding flow conditions.

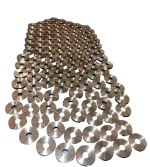

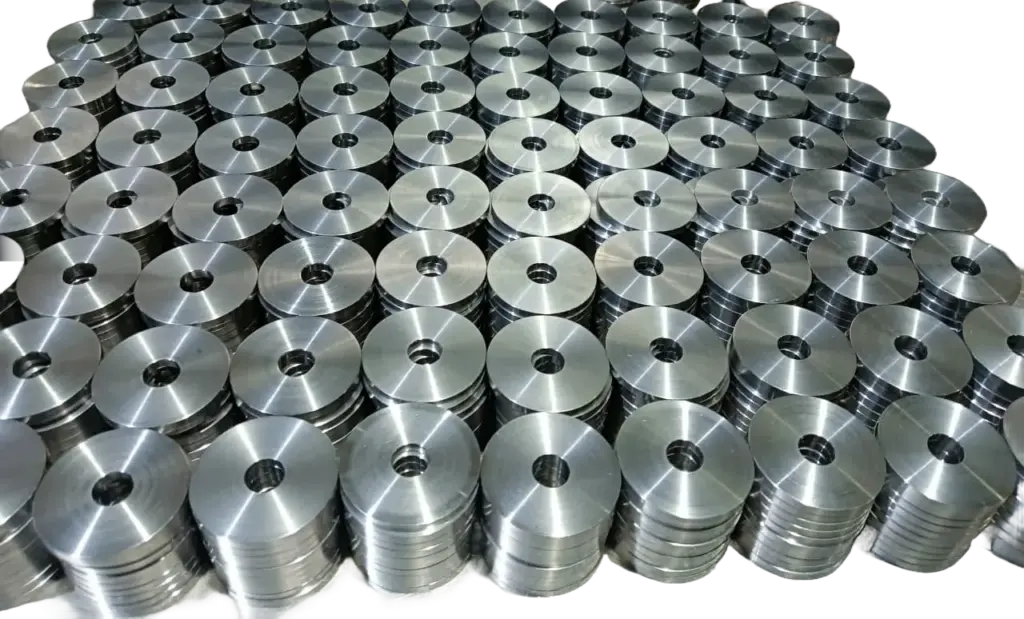

Used for spacing, alignment, and preload adjustment in pumps, motors, and machinery. Provide accurate thickness and flatness for OEM and assembly use.

Copper washers for hydraulic, fuel, and instrumentation systems. Soft metal ensures tight sealing under low bolt load with good corrosion resistance.

Lightweight, precision-machined rings for aerospace and compact machinery. Ideal where low weight and tight tolerances are essential.

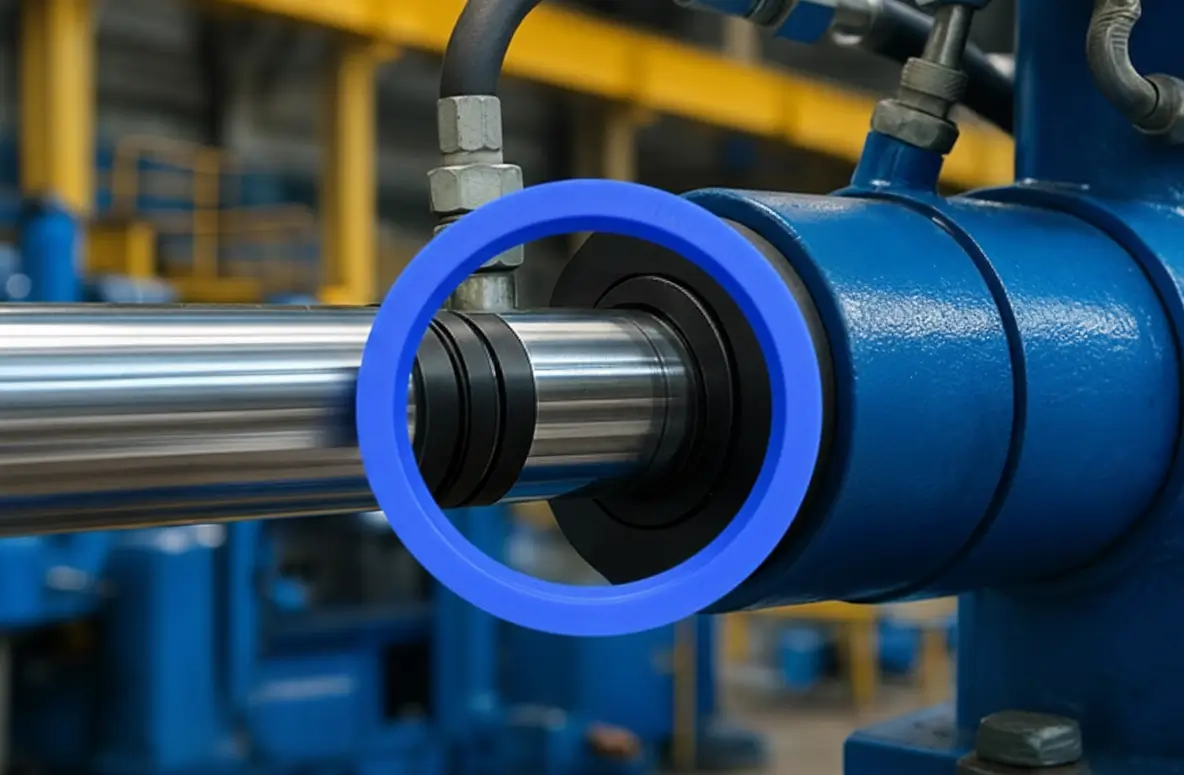

General-purpose sealing rings for hydraulic, pneumatic, and industrial equipment. Available in multiple materials for chemical, oil, and heat resistance.

High-performance metal seals for aerospace, vacuum, cryogenic, and high-temperature systems. Withstand extreme pressure and harsh industrial environments.

Thread-seal gaskets for boilers, vessels, heat exchangers, and inspection plugs. Provide tight leak protection under high pressure and temperature.

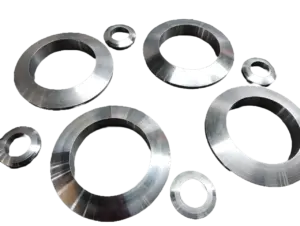

Semi-finished rings for RTJ gaskets, lenses, and valve components. Offer smooth surfaces and accurate concentricity for faster machining.

Strong, seamless rings for flanges, bearings, and pressure vessels. Deliver excellent mechanical strength and fatigue resistance across various alloys.

Custom precision parts for valves, pumps, drilling tools, and aerospace systems. Machined to tight tolerances in SS, Duplex, Inconel, Titanium, and alloys.

High-performance gaskets for refineries, heat exchangers, and pipelines. Metal winding + soft filler ensures reliable sealing under pressure and temperature changes.

Advanced seals with internal springs for aerospace, cryogenic, and ultra-high-pressure service. Maintain constant sealing force even in extreme conditions.

Our sealing solutions are trusted by a wide range of demanding industries, including:

Trusted industrial sensors, instrumentation & automation.

When to Replace Rupture Discs in Pressure Equipment: A Maintenance...

Read MoreFlange Sealing Solutions for High-Pressure Pipes: Zero Leakage Strategies In...

Read MoreHow to Select Pressure Relief Valves for Industrial Plants If...

Read MoreHow Rupture Discs Protect Pressure Systems from Catastrophic Failure In...

Read More

ADYAA Sealing Solutions offers durable, high-quality products for a leak-free operation you can trust. Contact us to find your perfect sealing solution.

ADYAA ENGINEERING

Unit 3, 5 Murphy Street

O’Connor, Perth WA 6163

Australia

Contact: