In the vast ecosystem of process control, temperature is often the most critical variable. Whether you are refining crude oil, pasteurizing milk, or managing chemical reactions, accurate temperature data is non-negotiable.

However, the sensors that measure this temperature—Resistance Temperature Detectors (RTDs) and Thermocouples—are often delicate devices.

Shutterstock

They contain fine wires and sensitive elements that would be destroyed instantly if exposed directly to high-velocity steam, corrosive acids, or abrasive slurries.

Enter the Thermowell.

Often overlooked as a simple metal fitting, the thermowell is actually a critical safety barrier. ADYAA, knows that selecting the wrong thermowell doesn’t just mean a broken sensor; it can lead to catastrophic vessel failure. In this guide, we break down everything you need to know about thermowells and their role in process instrumentation.

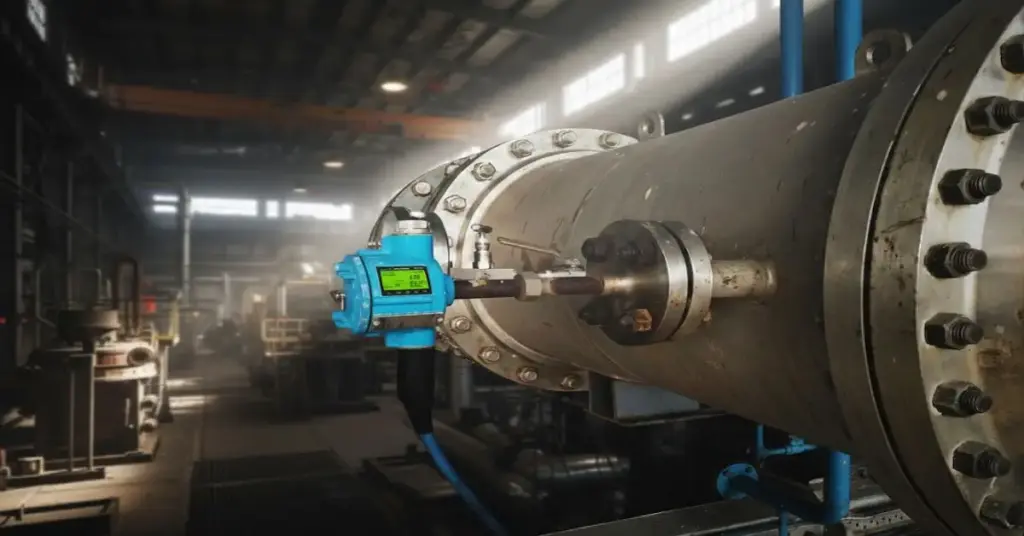

A Thermowell is a cylindrical pressure-tight fitting that protects temperature sensors from the process media. Think of it as “armor” for your sensor.

It is installed directly into the pipe or vessel, and the temperature sensor (the probe) is inserted into the open end of the thermowell. The heat transfers from the process fluid, through the thermowell wall, and into the sensor.

Not all thermowells are simple tubes. The shape of the “stem” (the part immersed in the fluid) dictates how the well handles pressure and how fast it responds to temperature changes.

The same diameter along the entire immersion length.

The diameter is reduced (stepped down) at the tip where the sensor sits.

The diameter gradually decreases from the root to the tip.

This is the most technical and critical part of thermowell selection.

When fluid flows past a thermowell, it doesn’t just flow smoothly; it creates vortices (swirls) that shed from alternating sides of the stem. This is known as the Von Karman Vortex Street.

These shedding vortices create oscillating forces that make the thermowell vibrate.

The Solution: Always perform a Wake Frequency Calculation (per ASME PTC 19.3 TW-2016 standards) before installing thermowells in high-velocity lines. This calculation ensures the stem is thick enough and short enough to withstand the flow.

Since the thermowell is in direct contact with the media, material selection is vital to prevent corrosion.

A thermowell might look like a simple piece of metal, but it is a highly engineered component that bridges the gap between delicate electronics and brutal industrial forces.

Ignoring the details—like immersion length, material compatibility, or wake frequency—can lead to poor measurement accuracy or dangerous mechanical failures.

ADYAA specializes in understanding that instrumentation isn’t just about reading a number on a screen; it’s about the safety and efficiency of your entire plant.

Need help sizing the right thermowell for your application?

Contact ADYAA’s Instrumentation Team

Let us handle your Wake Frequency Calculations and material selection today.