Maintaining product quality while keeping up with high-speed production is crucial. Vision and imaging sensors are now key components of automated inspection systems, providing fast, reliable, and precise visual analysis that replaces slower, error-prone manual checks.

ADYAA, offers advanced vision and imaging sensors that help manufacturers enhance quality, reduce defects, and increase overall production efficiency.

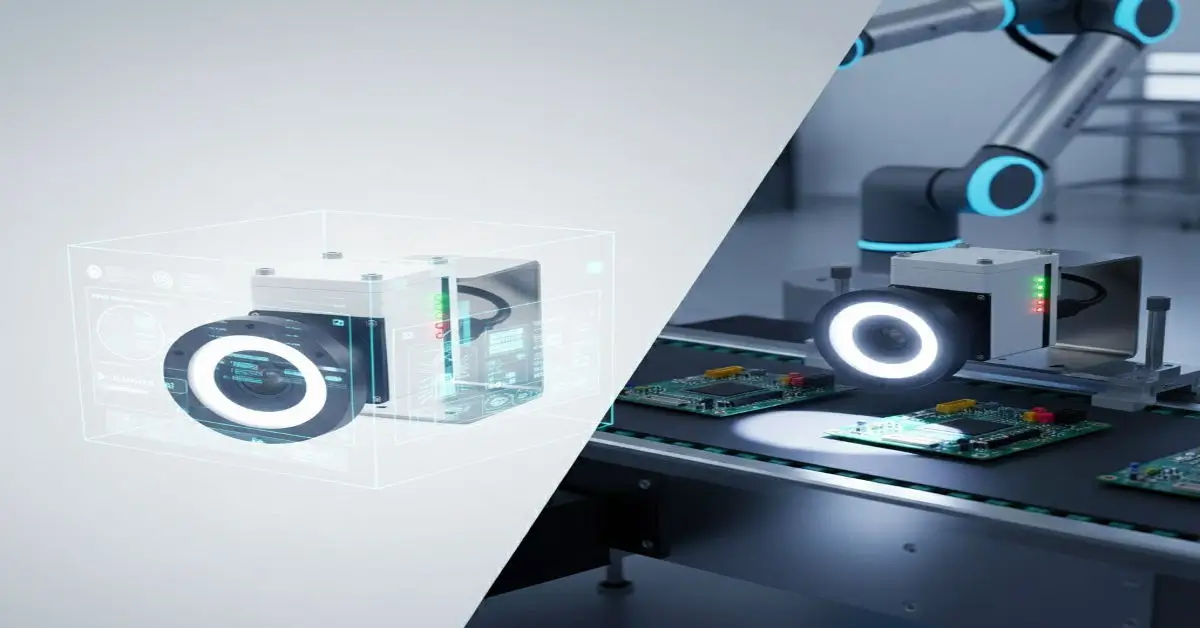

Vision and imaging sensors are compact devices that integrate a camera, illumination, optics, and embedded image-processing software into a single industrial-grade unit. These sensors capture images of products or processes and analyze visual features such as shape, size, color, and defects in real time.

Key capabilities include:

Vision sensors at ADYAA are designed for industrial environments and can handle high-speed production and complex inspection tasks across multiple industries.

Vision sensors enhance automated inspection by making processes faster, more accurate, and consistent:

Vision and imaging sensors are widely used to ensure quality and efficiency in multiple industries:

These applications demonstrate the importance of vision sensors in automotive, electronics, packaging, food processing, and pharmaceutical manufacturing.

Vision and imaging sensors are transforming automated inspection systems by delivering fast, accurate, and consistent quality checks. Integrating vision sensors from ADYAA Made by Baumer allows manufacturers to reduce waste, improve product quality, and collect valuable data for continuous process improvement.

Investing in advanced vision and imaging technology is key to creating smarter, more efficient, and reliable manufacturing operations.

Explore ADYAA’s Vision & Imaging Sensors Collection

Contact ADYAA’s technical team for expert advice