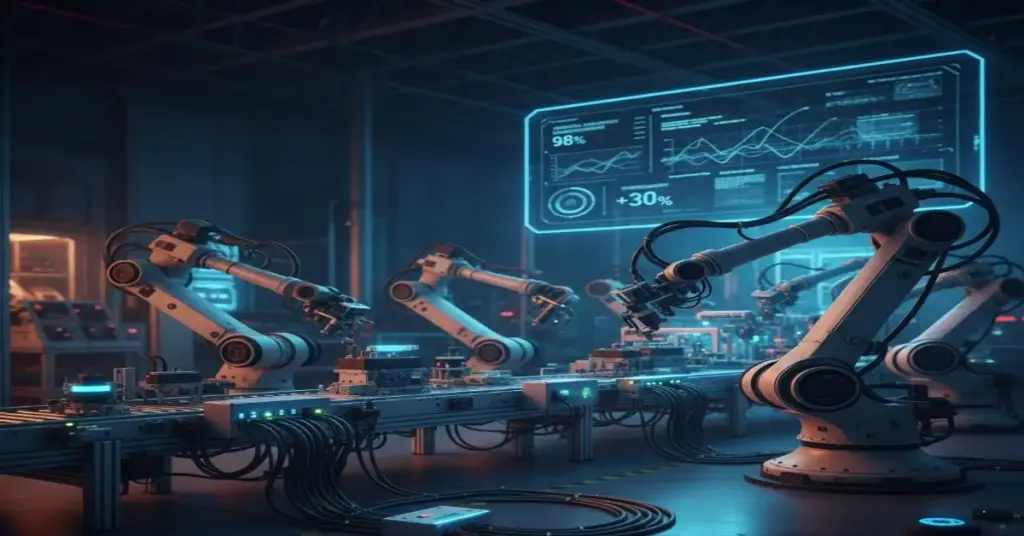

In modern manufacturing, efficiency, accuracy, and reliability are more important than ever. Industrial automation sensors play a pivotal role in helping manufacturers achieve these objectives. ADYAA offers high-quality industrial sensors designed by Prominent Brands including Baumer to enhance productivity, reduce downtime, and ensure consistent product quality.

Industrial automation sensors are devices that detect changes in physical parameters and communicate this information to control systems. By delivering real-time data, these sensors allow machines to operate optimally and adapt quickly to precise conditions.

ADYAA’s sensors are suitable for diverse industries including automotive, electronics, food processing, and pharmaceuticals.

Automation thrives on accurate, real-time information. Industrial sensors offer multiple advantages:

Beyond automation, sensors contribute to smoother and more efficient operations:

Industrial automation sensors provide the essential real-time insights manufacturers need for smarter, faster, and safer production. Using ADYAA’s advanced sensors, businesses can reduce waste, improve quality, save energy, and minimize downtime. Investing in cutting-edge sensors is a vital step toward creating efficient, reliable, and high-performing manufacturing processes.

Next Steps:

Explore ADYAA’s Industrial Sensors Collection

Contact ADYAA’s technical team for expert advice